Ro

-

Professor Kwy-Ro Lee Appointed Distinguished Member of IEEE

Professor Kwy-Ro Lee from the Department of Electrical Engineering at KAIST was selected as a distinguished member of the Institute of Electrical and Electronics Engineers (IEEE) where his contribution to research development of the technological management of semiconductors was recognized.

Professor Lee earned his BS from Seoul National University and MS & Ph.D. from the University of Minnesota. He has been working as a professor in the Department of Electrical Engineering since 1986. He has also served as the president of the LG Electronics Research Center in 2005 and the president of the Nanoscience and Technology Center at KAIST in 2010.

IEEE is the largest professional association for the advancement of technology in electrical, electronics, computing and communication with 400,000 members in 160 countries. Only 0.1 percent of members with over ten years of service can be selected as distinguished members based on their research devotion for society.

2014.01.02 View 9585

Professor Kwy-Ro Lee Appointed Distinguished Member of IEEE

Professor Kwy-Ro Lee from the Department of Electrical Engineering at KAIST was selected as a distinguished member of the Institute of Electrical and Electronics Engineers (IEEE) where his contribution to research development of the technological management of semiconductors was recognized.

Professor Lee earned his BS from Seoul National University and MS & Ph.D. from the University of Minnesota. He has been working as a professor in the Department of Electrical Engineering since 1986. He has also served as the president of the LG Electronics Research Center in 2005 and the president of the Nanoscience and Technology Center at KAIST in 2010.

IEEE is the largest professional association for the advancement of technology in electrical, electronics, computing and communication with 400,000 members in 160 countries. Only 0.1 percent of members with over ten years of service can be selected as distinguished members based on their research devotion for society.

2014.01.02 View 9585 -

Professor Jung-Ro Yoon Appointed President of Korean Sociological Association

The Korean Sociological Association (KSA) announced that Professor Jung-Ro Yoon from the Department of Humanities and Social Science at KAIST has been appointed as the president of KSA.

KSA has been contributing in the development of sociology and academic exchange among its members as the largest academic association in the field of social science in Korea since 1957.

Professor Yoon said, “KSA is trying to contribute to finding new solutions for economic crises, inequality, environmental pollution, and other uncertainties that we have been facing. We will attempt to provide vision and hope for the future of the society with cooperation from both students and researchers under the motto ‘Sociology for Research, Play and Communication.’”

Dr. Yoon has been in the Department of Humanities and Social Science at KAIST since 1991 after earning her MA & Ph.D. degree from Harvard University. She introduced Science, Technology and Society (STS) into Korea and served as the leader of the Ethical, Legal and Social Implications (ELSI) Project for the Utilization of Human Genome Information.

2014.01.02 View 9393

Professor Jung-Ro Yoon Appointed President of Korean Sociological Association

The Korean Sociological Association (KSA) announced that Professor Jung-Ro Yoon from the Department of Humanities and Social Science at KAIST has been appointed as the president of KSA.

KSA has been contributing in the development of sociology and academic exchange among its members as the largest academic association in the field of social science in Korea since 1957.

Professor Yoon said, “KSA is trying to contribute to finding new solutions for economic crises, inequality, environmental pollution, and other uncertainties that we have been facing. We will attempt to provide vision and hope for the future of the society with cooperation from both students and researchers under the motto ‘Sociology for Research, Play and Communication.’”

Dr. Yoon has been in the Department of Humanities and Social Science at KAIST since 1991 after earning her MA & Ph.D. degree from Harvard University. She introduced Science, Technology and Society (STS) into Korea and served as the leader of the Ethical, Legal and Social Implications (ELSI) Project for the Utilization of Human Genome Information.

2014.01.02 View 9393 -

The key to Alzheimer disease, PET-MRI made in Korea

Professor Kyu-Sung Cho

- Simultaneous PET-MRI imaging system commercialization technology developed purely from domestic technology - - Inspiring achievement by KAIST, National NanoFab Center, Sogang University, Seoul National University Hospital –

Hopes are high for the potential of producing domestic products in the field of state-of-the-art medical imaging equipment that used to rely on imported products.

The joint research team (KAIST, Sogang University and Seoul National University) with KAIST Department of Nuclear and Quantum Engineering Professor Kyu-Sung Cho in charge, together with National Nanofab Institution (NNFC; Director Jae-Young Lee), has developed PET-MRI simultaneous imaging system with domestic technology only. The team successfully acquired brain images of 3 volunteers with the newly developed system.

PET-MRI is integrated state-of-the-art medical imaging equipment that combines the advantages of Magnetic Resonance Imaging (MRI) that shows anatomical images of the body and Position Emission Tomography (PET) that analyses cell activity and metabolism. Since the anatomical information and functional information can be seen simultaneously, the device can be used to diagnose early onset Alzheimer’s disease and is essential in biological science research, such as new medicine development.

The existing equipment used to take MRI and PET images separately due to the strong magnetic field generated by MRI and combine the images. Hence, it was time consuming and error-prone due to patient’s movement. There was a need to develop PET that functions within a magnetic field to create a simultaneous imaging system.

The newly developed integral PET-MRI has 3 technical characteristics: 1. PET detector without magnetic interference, 2. PET-MRI integration system, 3.PET-MRI imaging processing.

The PET detector is the most important factor and accounts for half the cost of the whole system. KAIST Professor Cho and NNFC Doctor Woo-Suk Seol’s team successfully developed the Silicon Photomultiplier (amplifies light coming into the radiation detector) that can be used in strong magnetic fields. The developed sensor has a global competitive edge since it optimises semiconductor processing to yield over 95% productivity and around 10% gamma radiation energy resolving power.

Sogang University Department and Electrical Engineering Professor Yong Choi developed cutting edge PET system using a new concept of electric charge signal transmission method and imaging location distinction circuit. The creativity and excellence of the research findings were recognised and hence published on the cover of Medical Physics in June.

Seoul National University Hospital Department of Nuclear Medicine Professor Jae-Sung Lee developed the Silicon Photomultiplier sensor based PET imaging reconstitution programme, MRI imaging based PET imaging revision technology and PET-MRI imaging integration software.

Furthermore, KAIST Department of Electrical Engineering Professor Hyun-Wook Park was responsible for the development of RF Shielding technology that enables simultaneous installation of PET and MRI and using this technology, he developed a head coil for the brain that can be connected to PET for installation.

Based on the technology describe above, the joint research team successfully developed PET-MRI system for brains and acquired PET-MRI integrated brain images from 3 volunteers last June.

In particular, this system has the distinct feature of a detachable PET module and MRI head coil to the existing whole body MRI, so that PET-MRI simultaneous imaging is possible with low installation cost.

Professor Cho said, “We have prepared the foundation of domestic commercial PET and the system has a competitive edge in the global market of PET-MRI system technology.” He continued, “It can reduce the cost of the increasing brain related disease diagnosis, including Alzheimer’s, dramatically.”

Funded by Ministry of Trade, Industry and Energy as an Industrial Foundation Technology Development Project (98 billion won in 7 years), the research applied for over 20 patents and 20 CSI theses.

Figure 1.Brain phantom images from developed PET-MRI system

Figure 2. Brain images from developed PET-MRI system

Figure 3. Domestic PET-MRI clinical trial

Figure 4. Head RF coil and PET detector inserted in MRI

Figure 5. Insertion type PET detector module

Figure 6. Silicon Photomultiplier sensor (Left) and flash crystal block (right)

Figure7. Silicon Photomultiplier sensor

Figure 8. PET detection principle

2013.11.28 View 15994

The key to Alzheimer disease, PET-MRI made in Korea

Professor Kyu-Sung Cho

- Simultaneous PET-MRI imaging system commercialization technology developed purely from domestic technology - - Inspiring achievement by KAIST, National NanoFab Center, Sogang University, Seoul National University Hospital –

Hopes are high for the potential of producing domestic products in the field of state-of-the-art medical imaging equipment that used to rely on imported products.

The joint research team (KAIST, Sogang University and Seoul National University) with KAIST Department of Nuclear and Quantum Engineering Professor Kyu-Sung Cho in charge, together with National Nanofab Institution (NNFC; Director Jae-Young Lee), has developed PET-MRI simultaneous imaging system with domestic technology only. The team successfully acquired brain images of 3 volunteers with the newly developed system.

PET-MRI is integrated state-of-the-art medical imaging equipment that combines the advantages of Magnetic Resonance Imaging (MRI) that shows anatomical images of the body and Position Emission Tomography (PET) that analyses cell activity and metabolism. Since the anatomical information and functional information can be seen simultaneously, the device can be used to diagnose early onset Alzheimer’s disease and is essential in biological science research, such as new medicine development.

The existing equipment used to take MRI and PET images separately due to the strong magnetic field generated by MRI and combine the images. Hence, it was time consuming and error-prone due to patient’s movement. There was a need to develop PET that functions within a magnetic field to create a simultaneous imaging system.

The newly developed integral PET-MRI has 3 technical characteristics: 1. PET detector without magnetic interference, 2. PET-MRI integration system, 3.PET-MRI imaging processing.

The PET detector is the most important factor and accounts for half the cost of the whole system. KAIST Professor Cho and NNFC Doctor Woo-Suk Seol’s team successfully developed the Silicon Photomultiplier (amplifies light coming into the radiation detector) that can be used in strong magnetic fields. The developed sensor has a global competitive edge since it optimises semiconductor processing to yield over 95% productivity and around 10% gamma radiation energy resolving power.

Sogang University Department and Electrical Engineering Professor Yong Choi developed cutting edge PET system using a new concept of electric charge signal transmission method and imaging location distinction circuit. The creativity and excellence of the research findings were recognised and hence published on the cover of Medical Physics in June.

Seoul National University Hospital Department of Nuclear Medicine Professor Jae-Sung Lee developed the Silicon Photomultiplier sensor based PET imaging reconstitution programme, MRI imaging based PET imaging revision technology and PET-MRI imaging integration software.

Furthermore, KAIST Department of Electrical Engineering Professor Hyun-Wook Park was responsible for the development of RF Shielding technology that enables simultaneous installation of PET and MRI and using this technology, he developed a head coil for the brain that can be connected to PET for installation.

Based on the technology describe above, the joint research team successfully developed PET-MRI system for brains and acquired PET-MRI integrated brain images from 3 volunteers last June.

In particular, this system has the distinct feature of a detachable PET module and MRI head coil to the existing whole body MRI, so that PET-MRI simultaneous imaging is possible with low installation cost.

Professor Cho said, “We have prepared the foundation of domestic commercial PET and the system has a competitive edge in the global market of PET-MRI system technology.” He continued, “It can reduce the cost of the increasing brain related disease diagnosis, including Alzheimer’s, dramatically.”

Funded by Ministry of Trade, Industry and Energy as an Industrial Foundation Technology Development Project (98 billion won in 7 years), the research applied for over 20 patents and 20 CSI theses.

Figure 1.Brain phantom images from developed PET-MRI system

Figure 2. Brain images from developed PET-MRI system

Figure 3. Domestic PET-MRI clinical trial

Figure 4. Head RF coil and PET detector inserted in MRI

Figure 5. Insertion type PET detector module

Figure 6. Silicon Photomultiplier sensor (Left) and flash crystal block (right)

Figure7. Silicon Photomultiplier sensor

Figure 8. PET detection principle

2013.11.28 View 15994 -

A beginner's book for engineering co-published by KAIST professors

A group of KAIST professors published a book (Korean) to draw public attention to engineering.

The book, titled ‘What is Engineering?’, was co-published by 19 KAIST engineering professors for future engineering students and readers interested in exploring what engineering is about.

The co-authors wish to show talented students how important, fun, and helpful engineering is in improving our everyday life even though it is still not a very popular major in Korea.The book contains general knowledge in a wide array of engieering fields such as mechanics, civil, electrical & electronics, materials, chemistry, aerospace, marine systems, nuclear, industrial design, knowledge service, and bio and brain.One of the co-authors who planned for the publication of this book, Pung-Hyun Sung, a professor of nuclear and quantum engineering, said, “Various information, including the history, roles and future prospects of engineering, is contained in this book. It will be a precious guide for future engineers and members of the general public who are interested in understanding why engineering is so important.”

2013.11.04 View 6360

A beginner's book for engineering co-published by KAIST professors

A group of KAIST professors published a book (Korean) to draw public attention to engineering.

The book, titled ‘What is Engineering?’, was co-published by 19 KAIST engineering professors for future engineering students and readers interested in exploring what engineering is about.

The co-authors wish to show talented students how important, fun, and helpful engineering is in improving our everyday life even though it is still not a very popular major in Korea.The book contains general knowledge in a wide array of engieering fields such as mechanics, civil, electrical & electronics, materials, chemistry, aerospace, marine systems, nuclear, industrial design, knowledge service, and bio and brain.One of the co-authors who planned for the publication of this book, Pung-Hyun Sung, a professor of nuclear and quantum engineering, said, “Various information, including the history, roles and future prospects of engineering, is contained in this book. It will be a precious guide for future engineers and members of the general public who are interested in understanding why engineering is so important.”

2013.11.04 View 6360 -

Nanowire Made of Diverse Materials May Become Marketable

- Technology to commercialize nanowire developed after 2 years of industrial-academic joint research -

- 2 million strands of 50nm-width, 20 cm-length nanowire mass producible in 2 hours –

A South Korean joint industrial-academic research team has developed the technology to put forward the commercialization of nanowire that is only a few nanometers wide. It is expected to be applied in various fields such as semiconductors, high performance sensors, and biodevices.

In cooperation with LG Innotek and the National Nanofab center, Professor Jun-Bo Yoon, from KAIST Department of Electrical Engineering, developed the technology to mass produce nanowire at any length with various materials. The research results are published on the online edition of Nano Letters on July 30th.

Nanowire has a long linear structure with its width at 100 nanometers at maximum. It is a multifunctional material that has yet undiscovered thermal, electric, and mechanical properties. Nanowire is highly acclaimed as a cutting-edge material with unique nano-level properties that can be applied in semiconductors, energy, biodevices, and optic devices.

Previously, nanowires had an extremely low synthesis rate that required three or four days to grow few millimeters. It was therefore difficult to produce the desired products using nanowires. Moreover, nanowires needed to be evenly arranged for practical application, but the traditional technology required complex post-treatment, not to mention the arrangement was not immaculate.

The research team applied semiconductor process instead of chemical synthesis to resolve these issues. The team first formed a pattern greater that of the target frequency by using a photo-engraving process on a silicon wafer board whose diameter was 20 centimeters, then repeatedly reduced the frequency to produce 100 nm ultrafine linear grid pattern. Based on this pattern, the research team applied the sputtering process to mass-produce nanowires in perfect shapes of 50 nm width and 20 cm maximum length.

The new technology requires neither a lengthy synthesis process nor post-cleaning to attain a perfectly aligned state. Thus, academic and industrial circles consider the technology has high possibilities for commercialization.

“The significance is in resolving the issues in traditional technology, such as low productivity, long manufacturing time, restrictions in material synthesis, and nanowire alignment,” commented Professor Yoon on this research. “Nanowires have not been widely applied in the industry, but this technology will bring forward the commercialization of high performance semiconductors, optic devices, and biodevices that make use of nanowires.”

2013.10.18 View 10901

Nanowire Made of Diverse Materials May Become Marketable

- Technology to commercialize nanowire developed after 2 years of industrial-academic joint research -

- 2 million strands of 50nm-width, 20 cm-length nanowire mass producible in 2 hours –

A South Korean joint industrial-academic research team has developed the technology to put forward the commercialization of nanowire that is only a few nanometers wide. It is expected to be applied in various fields such as semiconductors, high performance sensors, and biodevices.

In cooperation with LG Innotek and the National Nanofab center, Professor Jun-Bo Yoon, from KAIST Department of Electrical Engineering, developed the technology to mass produce nanowire at any length with various materials. The research results are published on the online edition of Nano Letters on July 30th.

Nanowire has a long linear structure with its width at 100 nanometers at maximum. It is a multifunctional material that has yet undiscovered thermal, electric, and mechanical properties. Nanowire is highly acclaimed as a cutting-edge material with unique nano-level properties that can be applied in semiconductors, energy, biodevices, and optic devices.

Previously, nanowires had an extremely low synthesis rate that required three or four days to grow few millimeters. It was therefore difficult to produce the desired products using nanowires. Moreover, nanowires needed to be evenly arranged for practical application, but the traditional technology required complex post-treatment, not to mention the arrangement was not immaculate.

The research team applied semiconductor process instead of chemical synthesis to resolve these issues. The team first formed a pattern greater that of the target frequency by using a photo-engraving process on a silicon wafer board whose diameter was 20 centimeters, then repeatedly reduced the frequency to produce 100 nm ultrafine linear grid pattern. Based on this pattern, the research team applied the sputtering process to mass-produce nanowires in perfect shapes of 50 nm width and 20 cm maximum length.

The new technology requires neither a lengthy synthesis process nor post-cleaning to attain a perfectly aligned state. Thus, academic and industrial circles consider the technology has high possibilities for commercialization.

“The significance is in resolving the issues in traditional technology, such as low productivity, long manufacturing time, restrictions in material synthesis, and nanowire alignment,” commented Professor Yoon on this research. “Nanowires have not been widely applied in the industry, but this technology will bring forward the commercialization of high performance semiconductors, optic devices, and biodevices that make use of nanowires.”

2013.10.18 View 10901 -

Jellyfish Exterminator Robot Developed

Formation Control demonstrated by JEROS

- Trial performance successfully completed with three assembly robots -

A team led by KAIST Civil and Environmental Engineering Department’s Professor Hyeon Myeong has just finished testing the cooperative assembly robot for jellyfish population control, named JEROS, in the field.

The rising number of accidents and financial losses by fishing industry, estimated at 300 billion won per year, caused by the recent swarm of jellyfish in coastal waters has been a major problem for many years. The research team led by Prof. Hyeon Myeong began developing an unmanned automated system capable of eradicating jellyfishin in 2009, and has since completed field-tests last year with success.

This year, JEROS’s performance and speed has been improved with the ability to work in formation as a cooperative group to efficiently exterminate jellyfish.

An unmanned aquatic robot JEROS with a mountable grinding part is buoyed by two cylindrical bodies that utilizes propulsion motors to move forward and reverse, as well as rotate 360 degrees. Furthermore, GIS (geographic information system)-based map data is used to specify the region for jellyfish extermination, which automatically calculates the path for the task. JEROS then navigates autonomously using a GPS (Global Positioning System) receiver and an INS(inertial navigation system).

The assembly robots maintain a set formation pattern, while calculating its course to perform jellyfish extermination. The advantage of this method is that there is no need for individual control of the robots. Only the leader robot requires the calculated path, and the other robots can simply follow in a formation by exchanging their location information via wireless communication (ZigBee method).

JEROS uses its propulsion speed to capture jellyfish into the grinding part on the bottom, which then suctions the jellyfish toward the propeller to be exterminated.

The field test results show that three assembly robots operating at 4 knots (7.2km/h) disposes jellyfish at the rate of about 900kg/h.

The research team has currently completed testing JEROS at Gyeongnam Masan Bay and is expected to further experiment and improve the performance at various environment and conditions.

JEROS may also be utilized for other purposes including marine patrols, prevention of oil spills and waste removal in the sea.

JEROS research has been funded by Ministry of Science, ICT and Future Planning and Ministry of Trade, Industry and Energy.

2013.09.27 View 18435

Jellyfish Exterminator Robot Developed

Formation Control demonstrated by JEROS

- Trial performance successfully completed with three assembly robots -

A team led by KAIST Civil and Environmental Engineering Department’s Professor Hyeon Myeong has just finished testing the cooperative assembly robot for jellyfish population control, named JEROS, in the field.

The rising number of accidents and financial losses by fishing industry, estimated at 300 billion won per year, caused by the recent swarm of jellyfish in coastal waters has been a major problem for many years. The research team led by Prof. Hyeon Myeong began developing an unmanned automated system capable of eradicating jellyfishin in 2009, and has since completed field-tests last year with success.

This year, JEROS’s performance and speed has been improved with the ability to work in formation as a cooperative group to efficiently exterminate jellyfish.

An unmanned aquatic robot JEROS with a mountable grinding part is buoyed by two cylindrical bodies that utilizes propulsion motors to move forward and reverse, as well as rotate 360 degrees. Furthermore, GIS (geographic information system)-based map data is used to specify the region for jellyfish extermination, which automatically calculates the path for the task. JEROS then navigates autonomously using a GPS (Global Positioning System) receiver and an INS(inertial navigation system).

The assembly robots maintain a set formation pattern, while calculating its course to perform jellyfish extermination. The advantage of this method is that there is no need for individual control of the robots. Only the leader robot requires the calculated path, and the other robots can simply follow in a formation by exchanging their location information via wireless communication (ZigBee method).

JEROS uses its propulsion speed to capture jellyfish into the grinding part on the bottom, which then suctions the jellyfish toward the propeller to be exterminated.

The field test results show that three assembly robots operating at 4 knots (7.2km/h) disposes jellyfish at the rate of about 900kg/h.

The research team has currently completed testing JEROS at Gyeongnam Masan Bay and is expected to further experiment and improve the performance at various environment and conditions.

JEROS may also be utilized for other purposes including marine patrols, prevention of oil spills and waste removal in the sea.

JEROS research has been funded by Ministry of Science, ICT and Future Planning and Ministry of Trade, Industry and Energy.

2013.09.27 View 18435 -

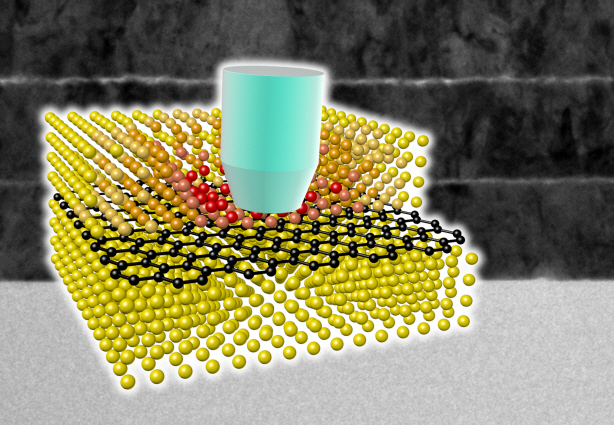

Ultra-High Strength Metamaterial Developed Using Graphene

New metamaterial has been developed, exhibiting hundreds of times greater strength than pure metals.

Professor Seung Min, Han and Yoo Sung, Jeong (Graduate School of Energy, Environment, Water, and Sustainability (EEWS)) and Professor Seok Woo, Jeon (Department of Material Science and Engineering) have developed a composite nanomaterial. The nanomaterial consists of graphene inserted in copper and nickel and exhibits strengths 500 times and 180 times, respectively, greater than that of pure metals. The result of the research was published on the July 2nd online edition in Nature Communications journal.

Graphene displays strengths 200 times greater than that of steel, is stretchable, and is flexible. The U.S. Army Armaments Research, Development and Engineering Center developed a graphene-metal nanomaterial but failed to drastically improve the strength of the material.

To maximize the strength increased by the addition of graphene, the KAIST research team created a layered structure of metal and graphene. Using CVD (Chemical Vapor Deposition), the team grew a single layer of graphene on a metal deposited substrate and then deposited another metal layer. They repeated this process to produce a metal-graphene multilayer composite material, utilizing a single layer of graphene. Micro-compression tests within Transmission Electronic Microscope and Molecular Dynamics simulations effectively showed the strength enhancing effect and the dislocation movement in grain boundaries of graphene on an atomic level.

The mechanical characteristics of the graphene layer within the metal-graphene composite material successfully blocked the dislocations and cracks from external damage from traveling inwards. Therefore the composite material displayed strength beyond conventional metal-metal multilayer materials. The copper-graphene multilayer material with an interplanar distance of 70nm exhibited 500 times greater (1.5GPa) strength than pure copper. Nickel-graphene multilayer material with an interplanar distance of 100nm showed 180 times greater (4.0GPa) strength than pure nickel.

It was found that there is a clear relationship between the interplanar distance and the strength of the multilayer material. A smaller interplanar distance made the dislocation movement more difficult and therefore increased the strength of the material. Professor Han, who led the research, commented, “the result is astounding as 0.00004% in weight of graphene increased the strength of the materials by hundreds of times” and “improvements based on this success, especially mass production with roll-to-roll process or metal sintering process in the production of ultra-high strength, lightweight parts for automobile and spacecraft, may become possible.” In addition, Professor Han mentioned that “the new material can be applied to coating materials for nuclear reactor construction or other structural materials requiring high reliability.”

The research project received support from National Research Foundation, Global Frontier Program, KAIST EEWS-KINC Program and KISTI Supercomputer and was a collaborative effort with KISTI (Korea Institute of Science and Technology Information), KBSI (Korea Basic Science Institute), Stanford University, and Columbia University.

A schematic diagram shows the structure of metal-graphene multi-layers. The metal-graphene multi-layered composite materials, containing a single-layered graphene, block the dislocation movement of graphene layers, resulting in a greater strength in the materials.

2013.08.23 View 19168

Ultra-High Strength Metamaterial Developed Using Graphene

New metamaterial has been developed, exhibiting hundreds of times greater strength than pure metals.

Professor Seung Min, Han and Yoo Sung, Jeong (Graduate School of Energy, Environment, Water, and Sustainability (EEWS)) and Professor Seok Woo, Jeon (Department of Material Science and Engineering) have developed a composite nanomaterial. The nanomaterial consists of graphene inserted in copper and nickel and exhibits strengths 500 times and 180 times, respectively, greater than that of pure metals. The result of the research was published on the July 2nd online edition in Nature Communications journal.

Graphene displays strengths 200 times greater than that of steel, is stretchable, and is flexible. The U.S. Army Armaments Research, Development and Engineering Center developed a graphene-metal nanomaterial but failed to drastically improve the strength of the material.

To maximize the strength increased by the addition of graphene, the KAIST research team created a layered structure of metal and graphene. Using CVD (Chemical Vapor Deposition), the team grew a single layer of graphene on a metal deposited substrate and then deposited another metal layer. They repeated this process to produce a metal-graphene multilayer composite material, utilizing a single layer of graphene. Micro-compression tests within Transmission Electronic Microscope and Molecular Dynamics simulations effectively showed the strength enhancing effect and the dislocation movement in grain boundaries of graphene on an atomic level.

The mechanical characteristics of the graphene layer within the metal-graphene composite material successfully blocked the dislocations and cracks from external damage from traveling inwards. Therefore the composite material displayed strength beyond conventional metal-metal multilayer materials. The copper-graphene multilayer material with an interplanar distance of 70nm exhibited 500 times greater (1.5GPa) strength than pure copper. Nickel-graphene multilayer material with an interplanar distance of 100nm showed 180 times greater (4.0GPa) strength than pure nickel.

It was found that there is a clear relationship between the interplanar distance and the strength of the multilayer material. A smaller interplanar distance made the dislocation movement more difficult and therefore increased the strength of the material. Professor Han, who led the research, commented, “the result is astounding as 0.00004% in weight of graphene increased the strength of the materials by hundreds of times” and “improvements based on this success, especially mass production with roll-to-roll process or metal sintering process in the production of ultra-high strength, lightweight parts for automobile and spacecraft, may become possible.” In addition, Professor Han mentioned that “the new material can be applied to coating materials for nuclear reactor construction or other structural materials requiring high reliability.”

The research project received support from National Research Foundation, Global Frontier Program, KAIST EEWS-KINC Program and KISTI Supercomputer and was a collaborative effort with KISTI (Korea Institute of Science and Technology Information), KBSI (Korea Basic Science Institute), Stanford University, and Columbia University.

A schematic diagram shows the structure of metal-graphene multi-layers. The metal-graphene multi-layered composite materials, containing a single-layered graphene, block the dislocation movement of graphene layers, resulting in a greater strength in the materials.

2013.08.23 View 19168 -

Two Dimensions of Value: Dopamine Neurons Represent Reward but not Aversiveness

Professor Christopher D. Fiorillo of the Bio & Brain Engineering (http://ineuron.kaist.ac.kr/web/home.html) at KAIST published a research paper in the August 2 issue of Science. The title of the paper is “Two Dimensions of Value: Dopamine Neurons Represent Reward but not Aversiveness.” The following is an introduction of his research work:

To make decisions, we need to estimate the value of sensory stimuli and motor actions, their “goodness” and “badness.” We can imagine that good and bad are two ends of a single continuum, or dimension, of value. This would be analogous to the single dimension of light intensity, which ranges from dark on one end to bright light on the other, with many shades of gray in between. Past models of behavior and learning have been based on a single continuum of value, and it has been proposed that a particular group of neurons (brain cells) that use dopamine as a neurotransmitter (chemical messenger) represent the single dimension of value, signaling both good and bad.

The experiments reported here show that dopamine neurons are sensitive to the value of reward but not punishment (like the aversiveness of a bitter taste). This demonstrates that reward and aversiveness are represented as two discrete dimensions (or categories) in the brain. “Reward” refers to the category of good things (food, water, sex, money, etc.), and “punishment” to the category of bad things (stimuli associated with harm to the body and that cause pain or other unpleasant sensations or emotions).

Rather than having one neurotransmitter (dopamine) to represent a single dimension of value, the present results imply the existence of four neurotransmitters to represent two dimensions of value. Dopamine signals evidence for reward (“gains”) and some other neurotransmitter presumably signals evidence against reward (“losses”). Likewise, there should be a neurotransmitter for evidence of danger and another for evidence of safety. It is interesting that there are three other neurotransmitters that are analogous to dopamine in many respects (serotonin, norepinephrine, and acetylcholine), and it is possible that they could represent the other three value signals.

For the research article, please visit: http://www.sciencemag.org/content/341/6145/546.abstract

For the Science 2nd issue, please visit: http://www.sciencemag.org/content/current#ResearchArticles

Illustration of Value Dimension

2013.08.08 View 9456

Two Dimensions of Value: Dopamine Neurons Represent Reward but not Aversiveness

Professor Christopher D. Fiorillo of the Bio & Brain Engineering (http://ineuron.kaist.ac.kr/web/home.html) at KAIST published a research paper in the August 2 issue of Science. The title of the paper is “Two Dimensions of Value: Dopamine Neurons Represent Reward but not Aversiveness.” The following is an introduction of his research work:

To make decisions, we need to estimate the value of sensory stimuli and motor actions, their “goodness” and “badness.” We can imagine that good and bad are two ends of a single continuum, or dimension, of value. This would be analogous to the single dimension of light intensity, which ranges from dark on one end to bright light on the other, with many shades of gray in between. Past models of behavior and learning have been based on a single continuum of value, and it has been proposed that a particular group of neurons (brain cells) that use dopamine as a neurotransmitter (chemical messenger) represent the single dimension of value, signaling both good and bad.

The experiments reported here show that dopamine neurons are sensitive to the value of reward but not punishment (like the aversiveness of a bitter taste). This demonstrates that reward and aversiveness are represented as two discrete dimensions (or categories) in the brain. “Reward” refers to the category of good things (food, water, sex, money, etc.), and “punishment” to the category of bad things (stimuli associated with harm to the body and that cause pain or other unpleasant sensations or emotions).

Rather than having one neurotransmitter (dopamine) to represent a single dimension of value, the present results imply the existence of four neurotransmitters to represent two dimensions of value. Dopamine signals evidence for reward (“gains”) and some other neurotransmitter presumably signals evidence against reward (“losses”). Likewise, there should be a neurotransmitter for evidence of danger and another for evidence of safety. It is interesting that there are three other neurotransmitters that are analogous to dopamine in many respects (serotonin, norepinephrine, and acetylcholine), and it is possible that they could represent the other three value signals.

For the research article, please visit: http://www.sciencemag.org/content/341/6145/546.abstract

For the Science 2nd issue, please visit: http://www.sciencemag.org/content/current#ResearchArticles

Illustration of Value Dimension

2013.08.08 View 9456 -

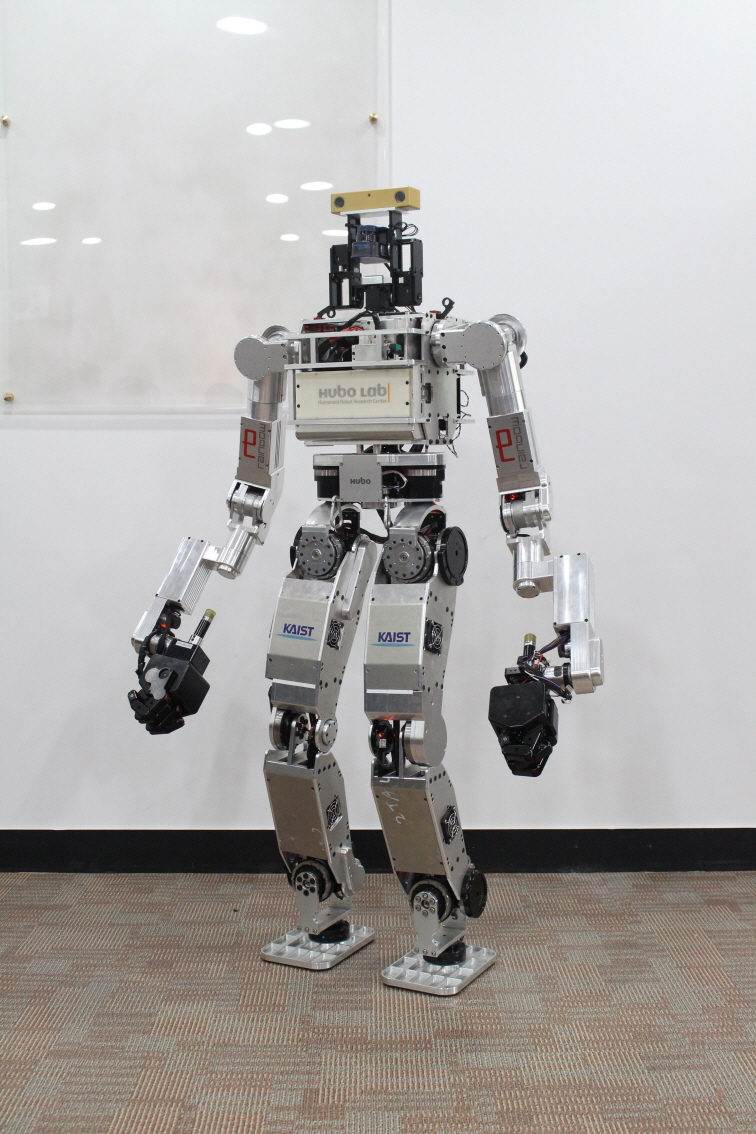

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 16158

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 16158 -

KAIST develops a low-power 60 GHz radio frequency chip for mobile devices

As the capacity of handheld devices increases to accommodate a greater number of functions, these devices have more memory, larger display screens, and the ability to play higher definition video files. If the users of mobile devices, including smartphones, tablet PCs, and notebooks, want to share or transfer data on one device with that of another device, a great deal of time and effort are needed.

As a possible method for the speedy transmission of large data, researchers are studying the adoption of gigabits per second (Gbps) wireless communications operating over the 60 gigahertz (GHz) frequency band. Some commercial approaches have been introduced for full-HD video streaming from a fixed source to a display by using the 60 GHz band. But mobile applications have not been developed yet because the 60 GHz radio frequency (RF) circuit consumes hundreds of milliwatts (mW) of DC power.

Professor Chul Soon Park from the Department of Electrical Engineering at the Korea Advanced Institute of Science and Technology (KAIST) and his research team recently developed a low-power version of the 60 GHz radio frequency integrated circuit (RFIC). Inside the circuit are an energy-efficient modulator performing amplification as well as modulation and a sensitivity-improved receiver employing a gain boosting demodulator.

The research team said that their RFIC draws as little as 67 mW of power in the 60 GHz frequency band, consuming 31mW to send and 36mW to receive large volumes of data. RFIC is also small enough to be mounted on smartphones or notebooks, requiring only one chip (its width, length, and height are about 1 mm) and one antenna (4x5x1 mm3) for sending and receiving data with an integrated switch.

Professor Park, Director of the Intelligent Radio Engineering Center at KAIST, gave an upbeat assessment of the potential of RFIC for future applications. What we have developed is a low-power 60-GHz RF chip with a transmission speed of 10.7 gigabits per second. In tests, we were able to stream uncompressed full-HD videos from a smartphone or notebook to a display without a cable connection (Youtube Link: http://www.youtube.com/watch?v=6PVSLBhMymc). Our chip can be installed on mobile devices or even on cameras so that the devices are virtually connected to other devices and able to exchange large data with each other."

2013.04.02 View 9842

KAIST develops a low-power 60 GHz radio frequency chip for mobile devices

As the capacity of handheld devices increases to accommodate a greater number of functions, these devices have more memory, larger display screens, and the ability to play higher definition video files. If the users of mobile devices, including smartphones, tablet PCs, and notebooks, want to share or transfer data on one device with that of another device, a great deal of time and effort are needed.

As a possible method for the speedy transmission of large data, researchers are studying the adoption of gigabits per second (Gbps) wireless communications operating over the 60 gigahertz (GHz) frequency band. Some commercial approaches have been introduced for full-HD video streaming from a fixed source to a display by using the 60 GHz band. But mobile applications have not been developed yet because the 60 GHz radio frequency (RF) circuit consumes hundreds of milliwatts (mW) of DC power.

Professor Chul Soon Park from the Department of Electrical Engineering at the Korea Advanced Institute of Science and Technology (KAIST) and his research team recently developed a low-power version of the 60 GHz radio frequency integrated circuit (RFIC). Inside the circuit are an energy-efficient modulator performing amplification as well as modulation and a sensitivity-improved receiver employing a gain boosting demodulator.

The research team said that their RFIC draws as little as 67 mW of power in the 60 GHz frequency band, consuming 31mW to send and 36mW to receive large volumes of data. RFIC is also small enough to be mounted on smartphones or notebooks, requiring only one chip (its width, length, and height are about 1 mm) and one antenna (4x5x1 mm3) for sending and receiving data with an integrated switch.

Professor Park, Director of the Intelligent Radio Engineering Center at KAIST, gave an upbeat assessment of the potential of RFIC for future applications. What we have developed is a low-power 60-GHz RF chip with a transmission speed of 10.7 gigabits per second. In tests, we were able to stream uncompressed full-HD videos from a smartphone or notebook to a display without a cable connection (Youtube Link: http://www.youtube.com/watch?v=6PVSLBhMymc). Our chip can be installed on mobile devices or even on cameras so that the devices are virtually connected to other devices and able to exchange large data with each other."

2013.04.02 View 9842 -

A Substance with Amazingly Improved Efficiency of Capturing Carbon Dioxides Developed

From left to right: Prof.Ali Coskun, Prof. Cafer T. Yavuz and Prof. Yousung Jung

- Selectivity of CO2 increased by 300 times in comparison to nitrogen, published in Nature Communications-

KAIST EEWS graduate school’s joint research team led by Prof. Cafer T. Yavuz, Prof. Ali Coskun, and Prof. Yousung Jung has developed the world"s most efficient CO2 absorbent that has 300 times higher carbon dioxide selectivity in comparison to nitrogen.

Recently, the importance of CCS* technology, which is about capturing, storing and treating carbon dioxides, has begun to emerge world-widely as a practical alternative for the response to climate change.

* CCS : Carbon Capture and sequestration

Current carbon dioxide capturing technologies are wet capturing using liquid absorbent, dry capturing using solid absorbent and separation-membrane capturing using a thin membrane like a film.

For the places like power plant and forge, where the emission of carbon dioxides is huge, the main task is to maintain the capturing efficiency under extremely hot and humid conditions.

The previously studied dry absorbents, such as MOF or zeolite, had the disadvantages of instability in moist conditions and expensive cost for synthesis.

On the other hand, the research team"s newly discovered dry absorbent, named ‘Azo-COP’, can be synthesized without any expensive catalysts so the production cost is very low. It is also stable under hot and humid conditions.

COP is a structure consisting of simple organic molecules combined into porous polymer and is the first dry carbon dioxide capturing material developed by this research team.

The research team introduced an additional functional group called "Azo" to the substance, so that it can selectively capture carbon dioxides among the mixture of gas.

Azo-COP, which includes ‘Azo’ functional group, is manufactured easily by using common synthesis methods, and impurities are removed simply by using cheap solvents like water and acetone instead of expensive catalysts. As a result, the manufacturing cost has lowered drastically.

Especially, Azo-COP is combined with carbon dioxides by weak attraction force rather than chemical attraction so the recycling energy cost for the absorbent can be reduced innovatively, and it is expected to be used for capturing substances other than carbon dioxides in various areas as it is stable under extreme conditions even under 350 degrees Celsius.

This research is supported by Korea Carbon Capture&Sequestration R&D Center(Head: Sangdo Park) and KAIST EEWS planning group.

Prof. Cafer T. Yavuz and Prof. Ali Coskun said that “when Azo-COP is used for separation of CO2 and N2, the capturing efficiency has increased by hundred times.” He continued “This substance does not need any catalysts and has great chemical characteristics like water stability and structure stability so is expected to be used in various fields including carbon dioxides capturing”

Meanwhile, this research is published in ‘Nature’s stablemate ‘Nature Communications’ on 15th of Jan.

2013.02.24 View 14131

A Substance with Amazingly Improved Efficiency of Capturing Carbon Dioxides Developed

From left to right: Prof.Ali Coskun, Prof. Cafer T. Yavuz and Prof. Yousung Jung

- Selectivity of CO2 increased by 300 times in comparison to nitrogen, published in Nature Communications-

KAIST EEWS graduate school’s joint research team led by Prof. Cafer T. Yavuz, Prof. Ali Coskun, and Prof. Yousung Jung has developed the world"s most efficient CO2 absorbent that has 300 times higher carbon dioxide selectivity in comparison to nitrogen.

Recently, the importance of CCS* technology, which is about capturing, storing and treating carbon dioxides, has begun to emerge world-widely as a practical alternative for the response to climate change.

* CCS : Carbon Capture and sequestration

Current carbon dioxide capturing technologies are wet capturing using liquid absorbent, dry capturing using solid absorbent and separation-membrane capturing using a thin membrane like a film.

For the places like power plant and forge, where the emission of carbon dioxides is huge, the main task is to maintain the capturing efficiency under extremely hot and humid conditions.

The previously studied dry absorbents, such as MOF or zeolite, had the disadvantages of instability in moist conditions and expensive cost for synthesis.

On the other hand, the research team"s newly discovered dry absorbent, named ‘Azo-COP’, can be synthesized without any expensive catalysts so the production cost is very low. It is also stable under hot and humid conditions.

COP is a structure consisting of simple organic molecules combined into porous polymer and is the first dry carbon dioxide capturing material developed by this research team.

The research team introduced an additional functional group called "Azo" to the substance, so that it can selectively capture carbon dioxides among the mixture of gas.

Azo-COP, which includes ‘Azo’ functional group, is manufactured easily by using common synthesis methods, and impurities are removed simply by using cheap solvents like water and acetone instead of expensive catalysts. As a result, the manufacturing cost has lowered drastically.

Especially, Azo-COP is combined with carbon dioxides by weak attraction force rather than chemical attraction so the recycling energy cost for the absorbent can be reduced innovatively, and it is expected to be used for capturing substances other than carbon dioxides in various areas as it is stable under extreme conditions even under 350 degrees Celsius.

This research is supported by Korea Carbon Capture&Sequestration R&D Center(Head: Sangdo Park) and KAIST EEWS planning group.

Prof. Cafer T. Yavuz and Prof. Ali Coskun said that “when Azo-COP is used for separation of CO2 and N2, the capturing efficiency has increased by hundred times.” He continued “This substance does not need any catalysts and has great chemical characteristics like water stability and structure stability so is expected to be used in various fields including carbon dioxides capturing”

Meanwhile, this research is published in ‘Nature’s stablemate ‘Nature Communications’ on 15th of Jan.

2013.02.24 View 14131 -

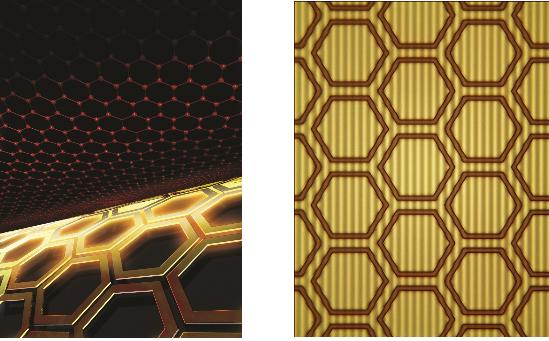

The control of light at the nano-level

Professor Min Bumki

Professor Min Bumki’s research team from the Department of Mechanical Engineering at KAIST have successfully gained control of the transmittance of light in optical devices using graphene* and artificial 2-dimensional metamaterials**.

* Graphene : a thin membrane composed of pure carbon, with atoms arranged in a regular hexagonal pattern

** Metamaterials : artificial materials engineered to have properties that may not be found in nature

The research results were published in the recent online edition (September 30th) of Nature Materials, a sister journal of the world renowned Nature journal, under the title ‘Terahertz waves with gate-controlled active graphene metamaterials’

Since the discovery of graphene in 2004 by Professors Novoselov and Geim from the University of Manchester (2010 Nobel Prize winners in Physics), it has been dubbed “the dream material” because of its outstanding physical properties.

Graphene has been especially praised for its ability to absorb approximately 2.3% of near infrared and visible rays due to its characteristic electron structure. This property allows graphene to be used as a transparent electrode, which is a vital electrical component used in touch screens and solar batteries. However, graphene’s optical transmittance was largely ignored by researchers due to its limited control using electrical methods and its small optical modulation in data transfer.

Professor Min’s team combined 0.34 nanometer-thick graphene with metamaterials to allow a more effective control of light transmittance and greater optical modulation. This graphene metamaterial can be integrated in to a thin and flexible macromolecule substrate which allows the control of transmittance using electric signals.

This research experimentally showed that graphene metamaterials can not only effective control optical transmittance, but can also be used in graphene optical memory devices using electrical hysteresis.

Professor Min said that “this research allows the effective control of light at the nanometer level” and that “this research will help in the development of microscopic optical modulators or memory disks”.

figure 1. The working drawing of graphene metamaterials

figure 2. Conceptual diagram (Left) and microscopic photo (right) of graphene metamaterials

2012.11.23 View 12161

The control of light at the nano-level

Professor Min Bumki

Professor Min Bumki’s research team from the Department of Mechanical Engineering at KAIST have successfully gained control of the transmittance of light in optical devices using graphene* and artificial 2-dimensional metamaterials**.

* Graphene : a thin membrane composed of pure carbon, with atoms arranged in a regular hexagonal pattern

** Metamaterials : artificial materials engineered to have properties that may not be found in nature

The research results were published in the recent online edition (September 30th) of Nature Materials, a sister journal of the world renowned Nature journal, under the title ‘Terahertz waves with gate-controlled active graphene metamaterials’

Since the discovery of graphene in 2004 by Professors Novoselov and Geim from the University of Manchester (2010 Nobel Prize winners in Physics), it has been dubbed “the dream material” because of its outstanding physical properties.

Graphene has been especially praised for its ability to absorb approximately 2.3% of near infrared and visible rays due to its characteristic electron structure. This property allows graphene to be used as a transparent electrode, which is a vital electrical component used in touch screens and solar batteries. However, graphene’s optical transmittance was largely ignored by researchers due to its limited control using electrical methods and its small optical modulation in data transfer.

Professor Min’s team combined 0.34 nanometer-thick graphene with metamaterials to allow a more effective control of light transmittance and greater optical modulation. This graphene metamaterial can be integrated in to a thin and flexible macromolecule substrate which allows the control of transmittance using electric signals.

This research experimentally showed that graphene metamaterials can not only effective control optical transmittance, but can also be used in graphene optical memory devices using electrical hysteresis.

Professor Min said that “this research allows the effective control of light at the nanometer level” and that “this research will help in the development of microscopic optical modulators or memory disks”.

figure 1. The working drawing of graphene metamaterials

figure 2. Conceptual diagram (Left) and microscopic photo (right) of graphene metamaterials

2012.11.23 View 12161