Ro

-

Emeritus Professor Jae-Kyu Lee Wins the AIS LEO Award

Emeritus Professor Jae-Kyu Lee has won the Association for Information Systems LEO Award 2020. Professor Lee, the first Korean to receive the LEO Award, was recognized for his research and development in preventative cyber security, which is a major part of the efforts he leads to realize what Professor Lee has named "Bright Internet."

Established in 1999, this award was named after the world’s first business application of computing, the Lyons Electronic Office and recognizes outstanding individuals in the field of information systems. The LEO Award recognized four winners including Professor Lee this year.

He has been professor and HHI Chair Professor at KAIST from 1985 to 2016 since he has received his Ph.D. in information and operations management from the Wharton School, University of Pennsylvania. He served as the Dean of College of Business and supervised around 30 doctoral students. He is currently the Distinguished Professor of School of Management at Xi’an Jiaotong University.

His research mainly focused on the creation of Bright Internet for preventive cybersecurity, improving relevance of research from Axiomatic Theories, and development of AI for electronic commerce and managerial decision support.

He is a fellow and was the president of the Association for Information Systems, and co-chaired the International Conference on Information Systems in 2017. He was the founder of Principles for the Bright Internet and established the Bright Internet Research Center at KAIST and Xi’an Jiatong University. He also established the Bright Internet Global Summit since ICIS 2017 in Seoul, and organized the Bright Internet Project Consortium in 2019 as a combined effort of academia-industry partnership. (www.brightinternet.org.)

He was a charter member of the Pacific Asia Conference in Information Systems, and served as conference chair. He was the founder editor-in-chief of the journal, Electronic Commerce Research and Applications (Elsevier), and was the founding chair of the International Conference on Electronic Commerce. In Korea, her served as president of Korea Society of Management Information Systems and Korea Society of Intelligent Information Systems.

"I am honored to be designated the first Korean winner of the honorable LEO Award," Lee said. "Based on my life-long efforts for developments in the field, I will continue to contribute to the research and development of information media systems."

2020.12.16 View 8416

Emeritus Professor Jae-Kyu Lee Wins the AIS LEO Award

Emeritus Professor Jae-Kyu Lee has won the Association for Information Systems LEO Award 2020. Professor Lee, the first Korean to receive the LEO Award, was recognized for his research and development in preventative cyber security, which is a major part of the efforts he leads to realize what Professor Lee has named "Bright Internet."

Established in 1999, this award was named after the world’s first business application of computing, the Lyons Electronic Office and recognizes outstanding individuals in the field of information systems. The LEO Award recognized four winners including Professor Lee this year.

He has been professor and HHI Chair Professor at KAIST from 1985 to 2016 since he has received his Ph.D. in information and operations management from the Wharton School, University of Pennsylvania. He served as the Dean of College of Business and supervised around 30 doctoral students. He is currently the Distinguished Professor of School of Management at Xi’an Jiaotong University.

His research mainly focused on the creation of Bright Internet for preventive cybersecurity, improving relevance of research from Axiomatic Theories, and development of AI for electronic commerce and managerial decision support.

He is a fellow and was the president of the Association for Information Systems, and co-chaired the International Conference on Information Systems in 2017. He was the founder of Principles for the Bright Internet and established the Bright Internet Research Center at KAIST and Xi’an Jiatong University. He also established the Bright Internet Global Summit since ICIS 2017 in Seoul, and organized the Bright Internet Project Consortium in 2019 as a combined effort of academia-industry partnership. (www.brightinternet.org.)

He was a charter member of the Pacific Asia Conference in Information Systems, and served as conference chair. He was the founder editor-in-chief of the journal, Electronic Commerce Research and Applications (Elsevier), and was the founding chair of the International Conference on Electronic Commerce. In Korea, her served as president of Korea Society of Management Information Systems and Korea Society of Intelligent Information Systems.

"I am honored to be designated the first Korean winner of the honorable LEO Award," Lee said. "Based on my life-long efforts for developments in the field, I will continue to contribute to the research and development of information media systems."

2020.12.16 View 8416 -

Researchers Report Longest-lived Aqueous Flow Batteries

New technology to overcome the life limit of next-generation water-cell batteries

A research team led by Professor Hee-Tak Kim from the Department of Chemical and Biomolecular Engineering has developed water-based zinc/bromine redox flow batteries (ZBBs) with the best life expectancy among all the redox flow batteries reported by identifying and solving the deterioration issue with zinc electrodes.

Professor Kim, head of the Advanced Battery Center at KAIST's Nano-fusion Research Institute, said, "We presented a new technology to overcome the life limit of next-generation water-cell batteries. Not only is it cheaper than conventional lithium-ion batteries, but it can contribute to the expansion of renewable energy and the safe supply of energy storage systems that can run with more than 80 percent energy efficiency."

ZBBs were found to have stable life spans of more than 5,000 cycles, even at a high current density of 100 mA/cm2. It was also confirmed that it represented the highest output and life expectancy compared to Redox flow batteries (RFBs) reported worldwide, which use other redox couples such as zinc-bromine, zinc-iodine, zinc-iron, and vanadium.

Recently, more attention has been focused on energy storage system (ESS) that can improve energy utilization efficiency by storing new and late-night power in large quantities and supplying it to the grid if necessary to supplement the intermittent nature of renewable energy and meet peak power demand.

However, lithium-ion batteries (LIBs), which are currently the core technology of ESSs, have been criticized for not being suitable for ESSs, which store large amounts of electricity due to their inherent risk of ignition and fire. In fact, a total of 33 cases of ESSs using LIBs in Korea had fire accidents, and 35% of all ESS facilities were shut down. This is estimated to have resulted in more than 700 billion won in losses.

As a result, water-based RFBs have drawn great attention. In particular, ZBBs that use ultra-low-cost bromide (ZnBr2) as an active material have been developed for ESSs since the 1970s, with their advantages of high cell voltage, high energy density, and low price compared to other RFBs. Until now, however, the commercialization of ZBBs has been delayed due to the short life span caused by the zinc electrodes. In particular, the uneven "dendrite" growth behavior of zinc metals during the charging and discharging process leads to internal short circuits in the battery which shorten its life.

The research team noted that self-aggregation occurs through the surface diffusion of zinc nuclei on the carbon electrode surface with low surface energy, and determined that self-aggregation was the main cause of zinc dendrite formation through quantum mechanics-based computer simulations and transmission electron microscopy. Furthermore, it was found that the surface diffusion of the zinc nuclei was inhibited in certain carbon fault structures so that dendrites were not produced.

Single vacancy defect, where one carbon atom is removed, exchanges zinc nuclei and electrons, and is strongly coupled, thus inhibiting surface diffusion and enabling uniform nuclear production/growth. The research team applied carbon electrodes with high density fault structure to ZBBs, achieving life characteristics of more than 5,000 cycles at a high charge current density (100 mA/cm2), which is 30 times that of LIBs.

This ESS technology, which can supply eco-friendly electric energy such as renewable energy to the private sector through technology that can drive safe and cheap redox flow batteries for long life, is expected to draw attention once again.

Publication:

Ju-Hyuk Lee, Riyul Kim, Soohyun Kim, Jiyun Heo, Hyeokjin Kwon, Jung Hoon Yang, and Hee-Tak Kim. 2020. Dendrite-free Zn electrodeposition triggered by interatomic orbital hybridization of Zn and single vacancy carbon defects for aqueous Zn-based flow batteries. Energy and Environmental Science, 2020, 13, 2839-2848.

Link to download the full-text paper:http://xlink.rsc.org/?DOI=D0EE00723D

Profile: Prof. Hee-Tak Kimheetak.kim@kaist.ac.krhttp://eed.kaist.ac.krAssociate ProfessorDepartment of Chemical & Biomolecular EngineeringKAIST

2020.12.16 View 15695

Researchers Report Longest-lived Aqueous Flow Batteries

New technology to overcome the life limit of next-generation water-cell batteries

A research team led by Professor Hee-Tak Kim from the Department of Chemical and Biomolecular Engineering has developed water-based zinc/bromine redox flow batteries (ZBBs) with the best life expectancy among all the redox flow batteries reported by identifying and solving the deterioration issue with zinc electrodes.

Professor Kim, head of the Advanced Battery Center at KAIST's Nano-fusion Research Institute, said, "We presented a new technology to overcome the life limit of next-generation water-cell batteries. Not only is it cheaper than conventional lithium-ion batteries, but it can contribute to the expansion of renewable energy and the safe supply of energy storage systems that can run with more than 80 percent energy efficiency."

ZBBs were found to have stable life spans of more than 5,000 cycles, even at a high current density of 100 mA/cm2. It was also confirmed that it represented the highest output and life expectancy compared to Redox flow batteries (RFBs) reported worldwide, which use other redox couples such as zinc-bromine, zinc-iodine, zinc-iron, and vanadium.

Recently, more attention has been focused on energy storage system (ESS) that can improve energy utilization efficiency by storing new and late-night power in large quantities and supplying it to the grid if necessary to supplement the intermittent nature of renewable energy and meet peak power demand.

However, lithium-ion batteries (LIBs), which are currently the core technology of ESSs, have been criticized for not being suitable for ESSs, which store large amounts of electricity due to their inherent risk of ignition and fire. In fact, a total of 33 cases of ESSs using LIBs in Korea had fire accidents, and 35% of all ESS facilities were shut down. This is estimated to have resulted in more than 700 billion won in losses.

As a result, water-based RFBs have drawn great attention. In particular, ZBBs that use ultra-low-cost bromide (ZnBr2) as an active material have been developed for ESSs since the 1970s, with their advantages of high cell voltage, high energy density, and low price compared to other RFBs. Until now, however, the commercialization of ZBBs has been delayed due to the short life span caused by the zinc electrodes. In particular, the uneven "dendrite" growth behavior of zinc metals during the charging and discharging process leads to internal short circuits in the battery which shorten its life.

The research team noted that self-aggregation occurs through the surface diffusion of zinc nuclei on the carbon electrode surface with low surface energy, and determined that self-aggregation was the main cause of zinc dendrite formation through quantum mechanics-based computer simulations and transmission electron microscopy. Furthermore, it was found that the surface diffusion of the zinc nuclei was inhibited in certain carbon fault structures so that dendrites were not produced.

Single vacancy defect, where one carbon atom is removed, exchanges zinc nuclei and electrons, and is strongly coupled, thus inhibiting surface diffusion and enabling uniform nuclear production/growth. The research team applied carbon electrodes with high density fault structure to ZBBs, achieving life characteristics of more than 5,000 cycles at a high charge current density (100 mA/cm2), which is 30 times that of LIBs.

This ESS technology, which can supply eco-friendly electric energy such as renewable energy to the private sector through technology that can drive safe and cheap redox flow batteries for long life, is expected to draw attention once again.

Publication:

Ju-Hyuk Lee, Riyul Kim, Soohyun Kim, Jiyun Heo, Hyeokjin Kwon, Jung Hoon Yang, and Hee-Tak Kim. 2020. Dendrite-free Zn electrodeposition triggered by interatomic orbital hybridization of Zn and single vacancy carbon defects for aqueous Zn-based flow batteries. Energy and Environmental Science, 2020, 13, 2839-2848.

Link to download the full-text paper:http://xlink.rsc.org/?DOI=D0EE00723D

Profile: Prof. Hee-Tak Kimheetak.kim@kaist.ac.krhttp://eed.kaist.ac.krAssociate ProfessorDepartment of Chemical & Biomolecular EngineeringKAIST

2020.12.16 View 15695 -

A Comprehensive Review of Biosynthesis of Inorganic Nanomaterials Using Microorganisms and Bacteriophages

There are diverse methods for producing numerous inorganic nanomaterials involving many experimental variables. Among the numerous possible matches, finding the best pair for synthesizing in an environmentally friendly way has been a longstanding challenge for researchers and industries.

A KAIST bioprocess engineering research team led by Distinguished Professor Sang Yup Lee conducted a summary of 146 biosynthesized single and multi-element inorganic nanomaterials covering 55 elements in the periodic table synthesized using wild-type and genetically engineered microorganisms. Their research highlights the diverse applications of biogenic nanomaterials and gives strategies for improving the biosynthesis of nanomaterials in terms of their producibility, crystallinity, size, and shape.

The research team described a 10-step flow chart for developing the biosynthesis of inorganic nanomaterials using microorganisms and bacteriophages. The research was published at Nature Review Chemistry as a cover and hero paper on December 3.

“We suggest general strategies for microbial nanomaterial biosynthesis via a step-by-step flow chart and give our perspectives on the future of nanomaterial biosynthesis and applications. This flow chart will serve as a general guide for those wishing to prepare biosynthetic inorganic nanomaterials using microbial cells,” explained Dr.Yoojin Choi, a co-author of this research.

Most inorganic nanomaterials are produced using physical and chemical methods and biological synthesis has been gaining more and more attention. However, conventional synthesis processes have drawbacks in terms of high energy consumption and non-environmentally friendly processes. Meanwhile, microorganisms such as microalgae, yeasts, fungi, bacteria, and even viruses can be utilized as biofactories to produce single and multi-element inorganic nanomaterials under mild conditions.

After conducting a massive survey, the research team summed up that the development of genetically engineered microorganisms with increased inorganic-ion-binding affinity, inorganic-ion-reduction ability, and nanomaterial biosynthetic efficiency has enabled the synthesis of many inorganic nanomaterials.

Among the strategies, the team introduced their analysis of a Pourbaix diagram for controlling the size and morphology of a product. The research team said this Pourbaix diagram analysis can be widely employed for biosynthesizing new nanomaterials with industrial applications.Professor Sang Yup Lee added, “This research provides extensive information and perspectives on the biosynthesis of diverse inorganic nanomaterials using microorganisms and bacteriophages and their applications. We expect that biosynthetic inorganic nanomaterials will find more diverse and innovative applications across diverse fields of science and technology.”

Dr. Choi started this research in 2018 and her interview about completing this extensive research was featured in an article at Nature Career article on December 4.

-ProfileDistinguished Professor Sang Yup Lee leesy@kaist.ac.krMetabolic &Biomolecular Engineering National Research Laboratoryhttp://mbel.kaist.ac.krDepartment of Chemical and Biomolecular EngineeringKAIST

2020.12.07 View 13143

A Comprehensive Review of Biosynthesis of Inorganic Nanomaterials Using Microorganisms and Bacteriophages

There are diverse methods for producing numerous inorganic nanomaterials involving many experimental variables. Among the numerous possible matches, finding the best pair for synthesizing in an environmentally friendly way has been a longstanding challenge for researchers and industries.

A KAIST bioprocess engineering research team led by Distinguished Professor Sang Yup Lee conducted a summary of 146 biosynthesized single and multi-element inorganic nanomaterials covering 55 elements in the periodic table synthesized using wild-type and genetically engineered microorganisms. Their research highlights the diverse applications of biogenic nanomaterials and gives strategies for improving the biosynthesis of nanomaterials in terms of their producibility, crystallinity, size, and shape.

The research team described a 10-step flow chart for developing the biosynthesis of inorganic nanomaterials using microorganisms and bacteriophages. The research was published at Nature Review Chemistry as a cover and hero paper on December 3.

“We suggest general strategies for microbial nanomaterial biosynthesis via a step-by-step flow chart and give our perspectives on the future of nanomaterial biosynthesis and applications. This flow chart will serve as a general guide for those wishing to prepare biosynthetic inorganic nanomaterials using microbial cells,” explained Dr.Yoojin Choi, a co-author of this research.

Most inorganic nanomaterials are produced using physical and chemical methods and biological synthesis has been gaining more and more attention. However, conventional synthesis processes have drawbacks in terms of high energy consumption and non-environmentally friendly processes. Meanwhile, microorganisms such as microalgae, yeasts, fungi, bacteria, and even viruses can be utilized as biofactories to produce single and multi-element inorganic nanomaterials under mild conditions.

After conducting a massive survey, the research team summed up that the development of genetically engineered microorganisms with increased inorganic-ion-binding affinity, inorganic-ion-reduction ability, and nanomaterial biosynthetic efficiency has enabled the synthesis of many inorganic nanomaterials.

Among the strategies, the team introduced their analysis of a Pourbaix diagram for controlling the size and morphology of a product. The research team said this Pourbaix diagram analysis can be widely employed for biosynthesizing new nanomaterials with industrial applications.Professor Sang Yup Lee added, “This research provides extensive information and perspectives on the biosynthesis of diverse inorganic nanomaterials using microorganisms and bacteriophages and their applications. We expect that biosynthetic inorganic nanomaterials will find more diverse and innovative applications across diverse fields of science and technology.”

Dr. Choi started this research in 2018 and her interview about completing this extensive research was featured in an article at Nature Career article on December 4.

-ProfileDistinguished Professor Sang Yup Lee leesy@kaist.ac.krMetabolic &Biomolecular Engineering National Research Laboratoryhttp://mbel.kaist.ac.krDepartment of Chemical and Biomolecular EngineeringKAIST

2020.12.07 View 13143 -

Team USRG’s Winning Streak Continues at the AI Grand Challenge

Team USRG (Unmanned Systems Research Group) led by Professor Hyunchul Shim from the School of Electrical Engineering has won the AI Grand Challenge 2020 held on Nov. 23 at Kintex in Ilsan, Kyonggi-do for the second consecutive year. The team received 7.7 million KRW in research funding from the Ministry of Science and ICT, the organizer of the challenge.

The team took a little over two minutes to complete the rescue operation mission of the challenge. The mission included swerving around seven obstacles, airdropping an aid package, and safely landing after identifying the landing spot. Their drone is the only one that successfully passed through a 10-meter tunnel out of five pre-qualified teams: three from universities and two from companies.

The AI Grand Challenge, which began in 2017, was designed to promote AI technology and its applications for addressing high-risk technical challenges, especially for conducting complex disaster relief operations.

For autonomous flying drones, swerving to avoid objects has always been an essential skill and a big challenge. For their flawless performance in the rescue operation, the team loaded an AI algorithm and upgraded their drone by improving the LiDAR-based localization system and a stronger propulsion system to carry more sensors. The drone weighs 2.4 kg and carries a small yet powerful computer with a GPU.

This AI-powered drone can complete rescue missions more efficiently in complicated and disastrous environments by precisely comprehending where the drone should go without needing GPS. The team also designed an all-in-one prop guard and installed a gripper onto the bottom of the drone to hold the aid package securely.

“We tried hard to improve our localization system better to resolve issues we had in the previous event,” said Professor Shim. Two PhD candidates, Han-Sob Lee and Bo-Sung Kim played a critical role in developing this drone.

After their two-year winning streak, their prize money now totals 2.4 billion KRW, equivalent to the winning prize of the DARPA Challenge. As the winning team, they will collaborate with other champions at the AI track challenge to develop rescue mission technology for a more complex environment.

“The importance of AI technology is continuing to grow and the government is providing large amounts of funding for research in this field. We would like to develop very competitive technology that will work in the real world,” Professor Shim added.

His group is investigating a wide array of AI technologies applicable to unmanned vehicles including indoor flying drones, self-driving cars, delivery robots, and a tram that circles the campus.

2020.12.01 View 10266

Team USRG’s Winning Streak Continues at the AI Grand Challenge

Team USRG (Unmanned Systems Research Group) led by Professor Hyunchul Shim from the School of Electrical Engineering has won the AI Grand Challenge 2020 held on Nov. 23 at Kintex in Ilsan, Kyonggi-do for the second consecutive year. The team received 7.7 million KRW in research funding from the Ministry of Science and ICT, the organizer of the challenge.

The team took a little over two minutes to complete the rescue operation mission of the challenge. The mission included swerving around seven obstacles, airdropping an aid package, and safely landing after identifying the landing spot. Their drone is the only one that successfully passed through a 10-meter tunnel out of five pre-qualified teams: three from universities and two from companies.

The AI Grand Challenge, which began in 2017, was designed to promote AI technology and its applications for addressing high-risk technical challenges, especially for conducting complex disaster relief operations.

For autonomous flying drones, swerving to avoid objects has always been an essential skill and a big challenge. For their flawless performance in the rescue operation, the team loaded an AI algorithm and upgraded their drone by improving the LiDAR-based localization system and a stronger propulsion system to carry more sensors. The drone weighs 2.4 kg and carries a small yet powerful computer with a GPU.

This AI-powered drone can complete rescue missions more efficiently in complicated and disastrous environments by precisely comprehending where the drone should go without needing GPS. The team also designed an all-in-one prop guard and installed a gripper onto the bottom of the drone to hold the aid package securely.

“We tried hard to improve our localization system better to resolve issues we had in the previous event,” said Professor Shim. Two PhD candidates, Han-Sob Lee and Bo-Sung Kim played a critical role in developing this drone.

After their two-year winning streak, their prize money now totals 2.4 billion KRW, equivalent to the winning prize of the DARPA Challenge. As the winning team, they will collaborate with other champions at the AI track challenge to develop rescue mission technology for a more complex environment.

“The importance of AI technology is continuing to grow and the government is providing large amounts of funding for research in this field. We would like to develop very competitive technology that will work in the real world,” Professor Shim added.

His group is investigating a wide array of AI technologies applicable to unmanned vehicles including indoor flying drones, self-driving cars, delivery robots, and a tram that circles the campus.

2020.12.01 View 10266 -

Simulations Open a New Way to Reverse Cell Aging

Turning off a newly identified enzyme could reverse a natural aging process in cells.

Research findings by a KAIST team provide insight into the complex mechanism of cellular senescence and present a potential therapeutic strategy for reducing age-related diseases associated with the accumulation of senescent cells.

Simulations that model molecular interactions have identified an enzyme that could be targeted to reverse a natural aging process called cellular senescence. The findings were validated with laboratory experiments on skin cells and skin equivalent tissues, and published in the Proceedings of the National Academy of Sciences (PNAS).

“Our research opens the door for a new generation that perceives aging as a reversible biological phenomenon,” says Professor Kwang-Hyun Cho of the Department of Bio and Brain engineering at the Korea Advanced Institute of Science and Technology (KAIST), who led the research with colleagues from KAIST and Amorepacific Corporation in Korea.

Cells respond to a variety of factors, such as oxidative stress, DNA damage, and shortening of the telomeres capping the ends of chromosomes, by entering a stable and persistent exit from the cell cycle. This process, called cellular senescence, is important, as it prevents damaged cells from proliferating and turning into cancer cells. But it is also a natural process that contributes to aging and age-related diseases. Recent research has shown that cellular senescence can be reversed. But the laboratory approaches used thus far also impair tissue regeneration or have the potential to trigger malignant transformations.

Professor Cho and his colleagues used an innovative strategy to identify molecules that could be targeted for reversing cellular senescence. The team pooled together information from the literature and databases about the molecular processes involved in cellular senescence. To this, they added results from their own research on the molecular processes involved in the proliferation, quiescence (a non-dividing cell that can re-enter the cell cycle) and senescence of skin fibroblasts, a cell type well known for repairing wounds. Using algorithms, they developed a model that simulates the interactions between these molecules. Their analyses allowed them to predict which molecules could be targeted to reverse cell senescence.

They then investigated one of the molecules, an enzyme called PDK1, in incubated senescent skin fibroblasts and three-dimensional skin equivalent tissue models. They found that blocking PDK1 led to the inhibition of two downstream signalling molecules, which in turn restored the cells’ ability to enter back into the cell cycle. Notably, the cells retained their capacity to regenerate wounded skin without proliferating in a way that could lead to malignant transformation.

The scientists recommend investigations are next done in organs and organisms to determine the full effect of PDK1 inhibition. Since the gene that codes for PDK1 is overexpressed in some cancers, the scientists expect that inhibiting it will have both anti-aging and anti-cancer effects.

-Profile

Professor Kwang-Hyun Cho

Laboratory for Systems Biology and Bio-Inspired Engineering

http://sbie.kaist.ac.kr

Department of Bio and Brain Engineering

KAIST

2020.11.26 View 14828

Simulations Open a New Way to Reverse Cell Aging

Turning off a newly identified enzyme could reverse a natural aging process in cells.

Research findings by a KAIST team provide insight into the complex mechanism of cellular senescence and present a potential therapeutic strategy for reducing age-related diseases associated with the accumulation of senescent cells.

Simulations that model molecular interactions have identified an enzyme that could be targeted to reverse a natural aging process called cellular senescence. The findings were validated with laboratory experiments on skin cells and skin equivalent tissues, and published in the Proceedings of the National Academy of Sciences (PNAS).

“Our research opens the door for a new generation that perceives aging as a reversible biological phenomenon,” says Professor Kwang-Hyun Cho of the Department of Bio and Brain engineering at the Korea Advanced Institute of Science and Technology (KAIST), who led the research with colleagues from KAIST and Amorepacific Corporation in Korea.

Cells respond to a variety of factors, such as oxidative stress, DNA damage, and shortening of the telomeres capping the ends of chromosomes, by entering a stable and persistent exit from the cell cycle. This process, called cellular senescence, is important, as it prevents damaged cells from proliferating and turning into cancer cells. But it is also a natural process that contributes to aging and age-related diseases. Recent research has shown that cellular senescence can be reversed. But the laboratory approaches used thus far also impair tissue regeneration or have the potential to trigger malignant transformations.

Professor Cho and his colleagues used an innovative strategy to identify molecules that could be targeted for reversing cellular senescence. The team pooled together information from the literature and databases about the molecular processes involved in cellular senescence. To this, they added results from their own research on the molecular processes involved in the proliferation, quiescence (a non-dividing cell that can re-enter the cell cycle) and senescence of skin fibroblasts, a cell type well known for repairing wounds. Using algorithms, they developed a model that simulates the interactions between these molecules. Their analyses allowed them to predict which molecules could be targeted to reverse cell senescence.

They then investigated one of the molecules, an enzyme called PDK1, in incubated senescent skin fibroblasts and three-dimensional skin equivalent tissue models. They found that blocking PDK1 led to the inhibition of two downstream signalling molecules, which in turn restored the cells’ ability to enter back into the cell cycle. Notably, the cells retained their capacity to regenerate wounded skin without proliferating in a way that could lead to malignant transformation.

The scientists recommend investigations are next done in organs and organisms to determine the full effect of PDK1 inhibition. Since the gene that codes for PDK1 is overexpressed in some cancers, the scientists expect that inhibiting it will have both anti-aging and anti-cancer effects.

-Profile

Professor Kwang-Hyun Cho

Laboratory for Systems Biology and Bio-Inspired Engineering

http://sbie.kaist.ac.kr

Department of Bio and Brain Engineering

KAIST

2020.11.26 View 14828 -

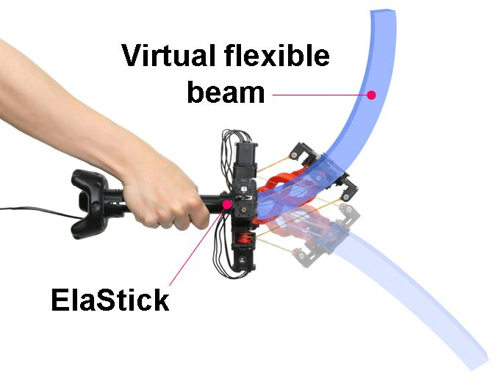

Feel the Force with ElaStick

ElaStick, a handheld variable stiffness display, renders the dynamic haptic response of a flexible object

Haptic controllers play an important role in providing rich and immersive virtual reality experiences. Professor Andrea Bianchi’s team in the Department of Industrial Design recreated the haptic response of flexible objects made of different materials and with different shapes by changing the stiffness of a custom-controller – ElaStick.

ElaStick is a portable hand-held force-feedback controller that is capable of rendering the illusion of how flexible and deformable objects feel when held in the hand. This VR haptic controller can change its stiffness in two directions independently and continuously. Since providing haptic feedback enhances the VR experience, researchers have suggested numerous approaches for rendering the physical properties of virtual objects - such as weights, the movement of mass, impacts, and damped oscillations.

The research team designed a new mechanism based on a quaternion joint and four variable-stiffness tendons. The quaternion joint is a two-DoF bending joint that enables ElaStick to bend and oscillate in any direction using a pair of tendons with varying stiffness. In fact, each tendon around the joint is made of a series of elastic rubber bands and inelastic fishing lines and can vary its stiffness by changing the proportion of the two materials. Thanks to these structures, each pair of tendons can behave independently, controlling the anisotropic characteristics of the entire device.

“The main challenge was to implement the mechanism to control the stiffness while maintaining independence between deformations in two perpendicular directions,” said Professor Bianchi.

The research team successfully measured the relative threshold of human perception on the stiffness of a handheld object. The results showed that the just-noticeable difference (JND) of human perception of stiffness is at most about 30% of the change from the initial value. It also found that appropriate haptic responses significantly enhance the quality of the VR experience. The research team surveyed the perceived realism, immersion, and enjoyment of participants after they played with various flexible objects in VR.

“It is meaningful that the haptic feedback of a flexible object was mechanically reproduced and its effectiveness in VR was proven. ElaStick has succeeded in implementing a novel mechanism to recreate the dynamic response of flexible objects that mimic real ones, suggesting a new category of haptic feedback that can be provided in VR,” explained Professor Bianchi.

The team plans to extend the ElaStick’s applications, from being used merely as a game controller to driving simulations, medical training, and many other digital contexts. This research, led by MS candidate Neung Ryu, won the Best Paper Award at the ACM UIST 2020 (the ACM Symposium on User Interface Software & Technology) last month.

-ProfileProfessor Andrea BianchiMakinteract.kaist.ac.krDepartment of Industrial DesignKAIST

2020.11.23 View 7840

Feel the Force with ElaStick

ElaStick, a handheld variable stiffness display, renders the dynamic haptic response of a flexible object

Haptic controllers play an important role in providing rich and immersive virtual reality experiences. Professor Andrea Bianchi’s team in the Department of Industrial Design recreated the haptic response of flexible objects made of different materials and with different shapes by changing the stiffness of a custom-controller – ElaStick.

ElaStick is a portable hand-held force-feedback controller that is capable of rendering the illusion of how flexible and deformable objects feel when held in the hand. This VR haptic controller can change its stiffness in two directions independently and continuously. Since providing haptic feedback enhances the VR experience, researchers have suggested numerous approaches for rendering the physical properties of virtual objects - such as weights, the movement of mass, impacts, and damped oscillations.

The research team designed a new mechanism based on a quaternion joint and four variable-stiffness tendons. The quaternion joint is a two-DoF bending joint that enables ElaStick to bend and oscillate in any direction using a pair of tendons with varying stiffness. In fact, each tendon around the joint is made of a series of elastic rubber bands and inelastic fishing lines and can vary its stiffness by changing the proportion of the two materials. Thanks to these structures, each pair of tendons can behave independently, controlling the anisotropic characteristics of the entire device.

“The main challenge was to implement the mechanism to control the stiffness while maintaining independence between deformations in two perpendicular directions,” said Professor Bianchi.

The research team successfully measured the relative threshold of human perception on the stiffness of a handheld object. The results showed that the just-noticeable difference (JND) of human perception of stiffness is at most about 30% of the change from the initial value. It also found that appropriate haptic responses significantly enhance the quality of the VR experience. The research team surveyed the perceived realism, immersion, and enjoyment of participants after they played with various flexible objects in VR.

“It is meaningful that the haptic feedback of a flexible object was mechanically reproduced and its effectiveness in VR was proven. ElaStick has succeeded in implementing a novel mechanism to recreate the dynamic response of flexible objects that mimic real ones, suggesting a new category of haptic feedback that can be provided in VR,” explained Professor Bianchi.

The team plans to extend the ElaStick’s applications, from being used merely as a game controller to driving simulations, medical training, and many other digital contexts. This research, led by MS candidate Neung Ryu, won the Best Paper Award at the ACM UIST 2020 (the ACM Symposium on User Interface Software & Technology) last month.

-ProfileProfessor Andrea BianchiMakinteract.kaist.ac.krDepartment of Industrial DesignKAIST

2020.11.23 View 7840 -

In Memory of Professor Dong-Soo Kim

Pioneering geotechnical engineer Dong-Soo Kim dies at 59

The Department of Civil and Environmental Engineering lost a pioneering scholar in geotechnical engineering, Professor Dong-Soo Kim. Professor Kim died on November 3, after a one-and-a-half-year battle with a brain tumor. He was 59.

Known for his piercing insight and infectious enthusiasm for the deepest questions in geotechnical science and engineering, Professor Kim built an extraordinary academic career while working at KAIST for 26 years. Professor Kim paved the way for establishing the geo-centrifuge experiment facilities at KAIST as part of the KOCED (Korea Construction Engineering Development Collaboratory Management Institute) Projects funded by the Ministry of Land, Infrastructure and Transport. He also served as director of the KOCED Geo-Centrifuge Center.

“He made significant contributions to the growth of the department since his joining and he was at the forefront of the globalization of the department. He passed away so early leaving behind so many projects,” lamented Professor Emeritus Chung-Bang Yun.

“Professor Kim insisted on lecturing despite his serious illness. He wanted to play his part so gracefully for his students until his last days,” said Professor Hyo-Gyong Kwak, the head of the department who was also a close colleague of 25 years. “His captivating warm smile and unwavering mentorship and guidance will be missed by students and faculty alike. We lost an exemplary leader, mentor, colleague, and friend.” One of his colleagues, Professor Gye-Chun Cho said, “We have lost a great professor and colleague in civil engineering worldwide. His impact and legacy will be remembered forever.”

Joining the KAIST faculty in 1994, he began his academic career at the Polytechnique University, New York for three years after earning his PhD at the University of Texas at Austin in 1991. He finished his BS and MS at Seoul National University in 1983 and 1985 respectively.

While at KAIST, he led the Soil Dynamics Lab in 1994 and researched on site characterization via field and lab tests. He also conducted geotechnical centrifuge tests on earthquake and offshore geotechnical problems. His research team studied the seismic design of geotechnical structures and explored the non-destructive testing and evaluation of civil structures.

Professor Kim made profound contributions to understanding fundamental geotechnical engineering problems. More recently, his lab investigated physical modeling using the geo-centrifuge testing machine that could simulate field geotechnical problems on small-scale models. Professor Kim’s perseverance, deep curiosity, and enthusiasm for discovery served him well in his roles as a teacher, mentor, and colleague in the department and beyond. “I thought of him as an elder brother who fully understand everything with generous mind,” said Professor Haeng-Ki Lee, former head of the department.

“I will never forget the hiking trip to Halla Mountain in Jeju last summer. He continuously cheered on the junior professors. Without him, we could not have made it to the summit. His support and encouragement always led us to produce good results and achievement in the labs,” remembered Professor Youngchul Kim. Taking great delight in helping young scientists, he inspired colleagues and students to find their own eureka moments. To professors like Jong-In Han and Ayoung Kim, he was the role model they hope to be due to his rigorous scholarship and generous character. Upon his passing, Professor Jaewook Myung reviewed all the emails he and Professor Kim has sent starting from his undergraduate days at KAIST. “He was my guiding light. He always listened attentively to my struggles from my undergraduate days and advised me very warmly.”

Professor Kim was also known for his key role in the Korean Geotechnical Society. His unmatched leadership led him to serve as the Chair of the Organizing Committee for the 19th International Conference on Soil Mechanics and Geotechnical Engineering in Seoul in 2017. He was the General Secretary of the 5th International Symposium on Deformation Characteristics of Geomaterials. He also served as a chair of the ISSSMGE TC 104 committee.

Professor Kim successfully carried out numerous projects with his research team and supervised more than 60 graduate students. For current students under his supervision, it is still tough to acknowledge the loss of their professor.

Master candidate Yeonjun Kim feels lost moving forward. PhD candidate Junsik Bae said that it is like a bad dream and he feels Professor Kim will still be in his lab whenever he goes inside. One of the staff members who worked with him, Byeol-Nim Cha, remembered that Professor Kim always entered the office with a big smile. “He always asked me how I am doing,” Cha added.

Professor Kim’s trailblazing research was recognized with several awards and honors. Cited as a Top 100 Scientist by the International Biographical Center (IBC) in 2008, Professor Kim received the Young Presidential Research Award from the Korean Academy of Science and Technology in 2002, the Korean Presidential Award on Civil Engineer’s Day in 2011, and the Telford Premium Rewards in 2018. Throughout his career, he authored or co-authored 321 papers in international journals and conference proceedings, and 278 papers in domestic journals and conferences.

President of the Korean Geotechnical Society Choong-gi Chung also eulogized him, “Above his impressive professional contributions, Professor Kim will be remembered forever for his generosity, simplicity, playfulness, and his smile.”

Professor Kim is survived by his wife, son, and daughter.

2020.11.19 View 9122

In Memory of Professor Dong-Soo Kim

Pioneering geotechnical engineer Dong-Soo Kim dies at 59

The Department of Civil and Environmental Engineering lost a pioneering scholar in geotechnical engineering, Professor Dong-Soo Kim. Professor Kim died on November 3, after a one-and-a-half-year battle with a brain tumor. He was 59.

Known for his piercing insight and infectious enthusiasm for the deepest questions in geotechnical science and engineering, Professor Kim built an extraordinary academic career while working at KAIST for 26 years. Professor Kim paved the way for establishing the geo-centrifuge experiment facilities at KAIST as part of the KOCED (Korea Construction Engineering Development Collaboratory Management Institute) Projects funded by the Ministry of Land, Infrastructure and Transport. He also served as director of the KOCED Geo-Centrifuge Center.

“He made significant contributions to the growth of the department since his joining and he was at the forefront of the globalization of the department. He passed away so early leaving behind so many projects,” lamented Professor Emeritus Chung-Bang Yun.

“Professor Kim insisted on lecturing despite his serious illness. He wanted to play his part so gracefully for his students until his last days,” said Professor Hyo-Gyong Kwak, the head of the department who was also a close colleague of 25 years. “His captivating warm smile and unwavering mentorship and guidance will be missed by students and faculty alike. We lost an exemplary leader, mentor, colleague, and friend.” One of his colleagues, Professor Gye-Chun Cho said, “We have lost a great professor and colleague in civil engineering worldwide. His impact and legacy will be remembered forever.”

Joining the KAIST faculty in 1994, he began his academic career at the Polytechnique University, New York for three years after earning his PhD at the University of Texas at Austin in 1991. He finished his BS and MS at Seoul National University in 1983 and 1985 respectively.

While at KAIST, he led the Soil Dynamics Lab in 1994 and researched on site characterization via field and lab tests. He also conducted geotechnical centrifuge tests on earthquake and offshore geotechnical problems. His research team studied the seismic design of geotechnical structures and explored the non-destructive testing and evaluation of civil structures.

Professor Kim made profound contributions to understanding fundamental geotechnical engineering problems. More recently, his lab investigated physical modeling using the geo-centrifuge testing machine that could simulate field geotechnical problems on small-scale models. Professor Kim’s perseverance, deep curiosity, and enthusiasm for discovery served him well in his roles as a teacher, mentor, and colleague in the department and beyond. “I thought of him as an elder brother who fully understand everything with generous mind,” said Professor Haeng-Ki Lee, former head of the department.

“I will never forget the hiking trip to Halla Mountain in Jeju last summer. He continuously cheered on the junior professors. Without him, we could not have made it to the summit. His support and encouragement always led us to produce good results and achievement in the labs,” remembered Professor Youngchul Kim. Taking great delight in helping young scientists, he inspired colleagues and students to find their own eureka moments. To professors like Jong-In Han and Ayoung Kim, he was the role model they hope to be due to his rigorous scholarship and generous character. Upon his passing, Professor Jaewook Myung reviewed all the emails he and Professor Kim has sent starting from his undergraduate days at KAIST. “He was my guiding light. He always listened attentively to my struggles from my undergraduate days and advised me very warmly.”

Professor Kim was also known for his key role in the Korean Geotechnical Society. His unmatched leadership led him to serve as the Chair of the Organizing Committee for the 19th International Conference on Soil Mechanics and Geotechnical Engineering in Seoul in 2017. He was the General Secretary of the 5th International Symposium on Deformation Characteristics of Geomaterials. He also served as a chair of the ISSSMGE TC 104 committee.

Professor Kim successfully carried out numerous projects with his research team and supervised more than 60 graduate students. For current students under his supervision, it is still tough to acknowledge the loss of their professor.

Master candidate Yeonjun Kim feels lost moving forward. PhD candidate Junsik Bae said that it is like a bad dream and he feels Professor Kim will still be in his lab whenever he goes inside. One of the staff members who worked with him, Byeol-Nim Cha, remembered that Professor Kim always entered the office with a big smile. “He always asked me how I am doing,” Cha added.

Professor Kim’s trailblazing research was recognized with several awards and honors. Cited as a Top 100 Scientist by the International Biographical Center (IBC) in 2008, Professor Kim received the Young Presidential Research Award from the Korean Academy of Science and Technology in 2002, the Korean Presidential Award on Civil Engineer’s Day in 2011, and the Telford Premium Rewards in 2018. Throughout his career, he authored or co-authored 321 papers in international journals and conference proceedings, and 278 papers in domestic journals and conferences.

President of the Korean Geotechnical Society Choong-gi Chung also eulogized him, “Above his impressive professional contributions, Professor Kim will be remembered forever for his generosity, simplicity, playfulness, and his smile.”

Professor Kim is survived by his wife, son, and daughter.

2020.11.19 View 9122 -

Engineered C. glutamicum Strain Capable of Producing High-Level Glutaric Acid from Glucose

An engineered C. glutamicum strain that can produce the world’s highest titer of glutaric acid was developed by employing systems metabolic engineering strategies

A metabolic engineering research group at KAIST has developed an engineered Corynebacterium glutamicum strain capable of producing high-level glutaric acid without byproducts from glucose. This new strategy will be useful for developing engineered micro-organisms for the bio-based production of value-added chemicals.

Glutaric acid, also known as pentanedioic acid, is a carboxylic acid that is widely used for various applications including the production of polyesters, polyamides, polyurethanes, glutaric anhydride, 1,5-pentanediol, and 5-hydroxyvaleric acid. Glutaric acid has been produced using various petroleum-based chemical methods, relying on non-renewable and toxic starting materials. Thus, various approaches have been taken to biologically produce glutaric acid from renewable resources. Previously, the development of the first glutaric acid producing Escherichia coli by introducing Pseudomonas putida genes was reported by a research group from KAIST, but the titer was low. Glutaric acid production by metabolically engineered Corynebacterium glutamicum has also been reported in several studies, but further improvements in glutaric acid production seemed possible since C. glutamicum has the capability of producing more than 130 g/L of L-lysine.

A research group comprised of Taehee Han, Gi Bae Kim, and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering addressed this issue. Their research paper “Glutaric acid production by systems metabolic engineering of an L-lysine-overproducing Corynebacterium glutamicum” was published online in PNAS on November 16, 2020.

This research reports the development of a metabolically engineered C. glutamicum strain capable of efficiently producing glutaric acid, starting from an L-lysine overproducer. The following novel strategies and approaches to achieve high-level glutaric acid production were employed. First, metabolic pathways in C. glutamicum were reconstituted for glutaric acid production by introducing P. putida genes. Then, multi-omics analyses including genome, transcriptome, and fluxome were conducted to understand the phenotype of the L-lysine overproducer strain. In addition to systematic understanding of the host strain, gene manipulation targets were predicted by omics analyses and applied for engineering C. glutamicum, which resulted in the development of an engineered strain capable of efficiently producing glutaric acid. Furthermore, the new glutaric acid exporter was discovered for the first time, which was used to further increase glutaric acid production through enhancing product excretion. Last but not least, culture conditions were optimized for high-level glutaric acid production. As a result, the final engineered strain was able to produce 105.3 g/L glutaric acid, the highest titer ever reported, in 69 hours by fed-batch fermentation.

Professor Sang Yup Lee said, “It is meaningful that we were able to develop a highly efficient glutaric acid producer capable of producing glutaric acid at the world’s highest titer without any byproducts from renewable carbon sources. This will further accelerate the bio-based production of valuable chemicals in pharmaceutical/medical/chemical industries.” This research was supported by the Bio & Medical Technology Development Program of the National Research Foundation and funded by the Ministry of Science and ICT.

-Profile

Distinguished Professor Sang Yup Lee

leesy@kaist.ac.kr

http://mbel.kaist.ac.kr

Department of Chemical and Biomolecular Engineering

KAIST

2020.11.17 View 8585

Engineered C. glutamicum Strain Capable of Producing High-Level Glutaric Acid from Glucose

An engineered C. glutamicum strain that can produce the world’s highest titer of glutaric acid was developed by employing systems metabolic engineering strategies

A metabolic engineering research group at KAIST has developed an engineered Corynebacterium glutamicum strain capable of producing high-level glutaric acid without byproducts from glucose. This new strategy will be useful for developing engineered micro-organisms for the bio-based production of value-added chemicals.

Glutaric acid, also known as pentanedioic acid, is a carboxylic acid that is widely used for various applications including the production of polyesters, polyamides, polyurethanes, glutaric anhydride, 1,5-pentanediol, and 5-hydroxyvaleric acid. Glutaric acid has been produced using various petroleum-based chemical methods, relying on non-renewable and toxic starting materials. Thus, various approaches have been taken to biologically produce glutaric acid from renewable resources. Previously, the development of the first glutaric acid producing Escherichia coli by introducing Pseudomonas putida genes was reported by a research group from KAIST, but the titer was low. Glutaric acid production by metabolically engineered Corynebacterium glutamicum has also been reported in several studies, but further improvements in glutaric acid production seemed possible since C. glutamicum has the capability of producing more than 130 g/L of L-lysine.

A research group comprised of Taehee Han, Gi Bae Kim, and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering addressed this issue. Their research paper “Glutaric acid production by systems metabolic engineering of an L-lysine-overproducing Corynebacterium glutamicum” was published online in PNAS on November 16, 2020.

This research reports the development of a metabolically engineered C. glutamicum strain capable of efficiently producing glutaric acid, starting from an L-lysine overproducer. The following novel strategies and approaches to achieve high-level glutaric acid production were employed. First, metabolic pathways in C. glutamicum were reconstituted for glutaric acid production by introducing P. putida genes. Then, multi-omics analyses including genome, transcriptome, and fluxome were conducted to understand the phenotype of the L-lysine overproducer strain. In addition to systematic understanding of the host strain, gene manipulation targets were predicted by omics analyses and applied for engineering C. glutamicum, which resulted in the development of an engineered strain capable of efficiently producing glutaric acid. Furthermore, the new glutaric acid exporter was discovered for the first time, which was used to further increase glutaric acid production through enhancing product excretion. Last but not least, culture conditions were optimized for high-level glutaric acid production. As a result, the final engineered strain was able to produce 105.3 g/L glutaric acid, the highest titer ever reported, in 69 hours by fed-batch fermentation.

Professor Sang Yup Lee said, “It is meaningful that we were able to develop a highly efficient glutaric acid producer capable of producing glutaric acid at the world’s highest titer without any byproducts from renewable carbon sources. This will further accelerate the bio-based production of valuable chemicals in pharmaceutical/medical/chemical industries.” This research was supported by the Bio & Medical Technology Development Program of the National Research Foundation and funded by the Ministry of Science and ICT.

-Profile

Distinguished Professor Sang Yup Lee

leesy@kaist.ac.kr

http://mbel.kaist.ac.kr

Department of Chemical and Biomolecular Engineering

KAIST

2020.11.17 View 8585 -

Professor Kyu-Young Whang Donates Toward the 50th Anniversary Memorial Building

Distinguished Professor Kyu-Young Whang from the School of Computing made a gift of 100 million KRW toward the construction of the 50th Anniversary Memorial Building during a ceremony on November 3 at the Daejeon campus. "As a member of the first class of KAIST, I feel very delighted to play a part in the fundraising campaign for the 50th anniversary celebration. This is also a token of appreciation to my alma mater and I look forward to alumni and the KAIST community joining this campaign," said Professor Emeritus Whang. KAIST will name the Kyu-Young Whang and Jonghae Song Christian Seminar Room at the 50th Anniversary Memorial Building. The ground will be broken in 2022 for construction of the building.

2020.11.04 View 7865

Professor Kyu-Young Whang Donates Toward the 50th Anniversary Memorial Building

Distinguished Professor Kyu-Young Whang from the School of Computing made a gift of 100 million KRW toward the construction of the 50th Anniversary Memorial Building during a ceremony on November 3 at the Daejeon campus. "As a member of the first class of KAIST, I feel very delighted to play a part in the fundraising campaign for the 50th anniversary celebration. This is also a token of appreciation to my alma mater and I look forward to alumni and the KAIST community joining this campaign," said Professor Emeritus Whang. KAIST will name the Kyu-Young Whang and Jonghae Song Christian Seminar Room at the 50th Anniversary Memorial Building. The ground will be broken in 2022 for construction of the building.

2020.11.04 View 7865 -

Chemical Scissors Snip 2D Transition Metal Dichalcogenides into Nanoribbon

New ‘nanoribbon’ catalyst should slash cost of hydrogen production for clean fuels

Researchers have identified a potential catalyst alternative – and an innovative way to produce them using chemical ‘scissors’ – that could make hydrogen production more economical.

The research team led by Professor Sang Ouk Kim at the Department of Materials Science and Engineering published their work in Nature Communications.

Hydrogen is likely to play a key role in the clean transition away from fossil fuels and other processes that produce greenhouse gas emissions. There is a raft of transportation sectors such as long-haul shipping and aviation that are difficult to electrify and so will require cleanly produced hydrogen as a fuel or as a feedstock for other carbon-neutral synthetic fuels. Likewise, fertilizer production and the steel sector are unlikely to be “de-carbonized” without cheap and clean hydrogen.

The problem is that the cheapest methods by far of producing hydrogen gas is currently from natural gas, a process that itself produces the greenhouse gas carbon dioxide–which defeats the purpose.

Alternative techniques of hydrogen production, such as electrolysis using an electric current between two electrodes plunged into water to overcome the chemical bonds holding water together, thereby splitting it into its constituent elements, oxygen and hydrogen are very well established. But one of the factors contributing to the high cost, beyond being extremely energy-intensive, is the need for the very expensive precious and relatively rare metal platinum. The platinum is used as a catalyst–a substance that kicks off or speeds up a chemical reaction–in the hydrogen production process.

As a result, researchers have long been on the hunt for a substitution for platinum -- another catalyst that is abundant in the earth and thus much cheaper.

Transition metal dichalcogenides, or TMDs, in a nanomaterial form, have for some time been considered a good candidate as a catalyst replacement for platinum. These are substances composed of one atom of a transition metal (the elements in the middle part of the periodic table) and two atoms of a chalcogen element (the elements in the third-to-last column in the periodic table, specifically sulfur, selenium and tellurium).

What makes TMDs a good bet as a platinum replacement is not just that they are much more abundant, but also their electrons are structured in a way that gives the electrodes a boost.

In addition, a TMD that is a nanomaterial is essentially a two-dimensional super-thin sheet only a few atoms thick, just like graphene. The ultrathin nature of a 2-D TMD nanosheet allows for a great many more TMD molecules to be exposed during the catalysis process than would be the case in a block of the stuff, thus kicking off and speeding up the hydrogen-making chemical reaction that much more.

However, even here the TMD molecules are only reactive at the four edges of a nanosheet. In the flat interior, not much is going on. In order to increase the chemical reaction rate in the production of hydrogen, the nanosheet would need to be cut into very thin – almost one-dimensional strips, thereby creating many edges.

In response, the research team developed what are in essence a pair of chemical scissors that can snip TMD into tiny strips.

“Up to now, the only substances that anyone has been able to turn into these ‘nano-ribbons’ are graphene and phosphorene,” said Sang Professor Kim, one of the researchers involved in devising the process.

“But they’re both made up of just one element, so it’s pretty straightforward. Figuring out how to do it for TMD, which is made of two elements was going to be much harder.”

The ‘scissors’ involve a two-step process involving first inserting lithium ions into the layered structure of the TMD sheets, and then using ultrasound to cause a spontaneous ‘unzipping’ in straight lines.

“It works sort of like how when you split a plank of plywood: it breaks easily in one direction along the grain,” Professor Kim continued. “It’s actually really simple.”

The researchers then tried it with various types of TMDs, including those made of molybdenum, selenium, sulfur, tellurium and tungsten. All worked just as well, with a catalytic efficiency as effective as platinum’s.

Because of the simplicity of the procedure, this method should be able to be used not just in the large-scale production of TMD nanoribbons, but also to make similar nanoribbons from other multi-elemental 2D materials for purposes beyond just hydrogen production.

-ProfileProfessor Sang Ouk KimSoft Nanomaterials Laboratory (http://snml.kaist.ac.kr)Department of Materials Science and EngineeringKAIST

2020.10.29 View 9949

Chemical Scissors Snip 2D Transition Metal Dichalcogenides into Nanoribbon

New ‘nanoribbon’ catalyst should slash cost of hydrogen production for clean fuels

Researchers have identified a potential catalyst alternative – and an innovative way to produce them using chemical ‘scissors’ – that could make hydrogen production more economical.

The research team led by Professor Sang Ouk Kim at the Department of Materials Science and Engineering published their work in Nature Communications.

Hydrogen is likely to play a key role in the clean transition away from fossil fuels and other processes that produce greenhouse gas emissions. There is a raft of transportation sectors such as long-haul shipping and aviation that are difficult to electrify and so will require cleanly produced hydrogen as a fuel or as a feedstock for other carbon-neutral synthetic fuels. Likewise, fertilizer production and the steel sector are unlikely to be “de-carbonized” without cheap and clean hydrogen.

The problem is that the cheapest methods by far of producing hydrogen gas is currently from natural gas, a process that itself produces the greenhouse gas carbon dioxide–which defeats the purpose.

Alternative techniques of hydrogen production, such as electrolysis using an electric current between two electrodes plunged into water to overcome the chemical bonds holding water together, thereby splitting it into its constituent elements, oxygen and hydrogen are very well established. But one of the factors contributing to the high cost, beyond being extremely energy-intensive, is the need for the very expensive precious and relatively rare metal platinum. The platinum is used as a catalyst–a substance that kicks off or speeds up a chemical reaction–in the hydrogen production process.

As a result, researchers have long been on the hunt for a substitution for platinum -- another catalyst that is abundant in the earth and thus much cheaper.

Transition metal dichalcogenides, or TMDs, in a nanomaterial form, have for some time been considered a good candidate as a catalyst replacement for platinum. These are substances composed of one atom of a transition metal (the elements in the middle part of the periodic table) and two atoms of a chalcogen element (the elements in the third-to-last column in the periodic table, specifically sulfur, selenium and tellurium).

What makes TMDs a good bet as a platinum replacement is not just that they are much more abundant, but also their electrons are structured in a way that gives the electrodes a boost.

In addition, a TMD that is a nanomaterial is essentially a two-dimensional super-thin sheet only a few atoms thick, just like graphene. The ultrathin nature of a 2-D TMD nanosheet allows for a great many more TMD molecules to be exposed during the catalysis process than would be the case in a block of the stuff, thus kicking off and speeding up the hydrogen-making chemical reaction that much more.

However, even here the TMD molecules are only reactive at the four edges of a nanosheet. In the flat interior, not much is going on. In order to increase the chemical reaction rate in the production of hydrogen, the nanosheet would need to be cut into very thin – almost one-dimensional strips, thereby creating many edges.

In response, the research team developed what are in essence a pair of chemical scissors that can snip TMD into tiny strips.

“Up to now, the only substances that anyone has been able to turn into these ‘nano-ribbons’ are graphene and phosphorene,” said Sang Professor Kim, one of the researchers involved in devising the process.

“But they’re both made up of just one element, so it’s pretty straightforward. Figuring out how to do it for TMD, which is made of two elements was going to be much harder.”

The ‘scissors’ involve a two-step process involving first inserting lithium ions into the layered structure of the TMD sheets, and then using ultrasound to cause a spontaneous ‘unzipping’ in straight lines.

“It works sort of like how when you split a plank of plywood: it breaks easily in one direction along the grain,” Professor Kim continued. “It’s actually really simple.”

The researchers then tried it with various types of TMDs, including those made of molybdenum, selenium, sulfur, tellurium and tungsten. All worked just as well, with a catalytic efficiency as effective as platinum’s.

Because of the simplicity of the procedure, this method should be able to be used not just in the large-scale production of TMD nanoribbons, but also to make similar nanoribbons from other multi-elemental 2D materials for purposes beyond just hydrogen production.

-ProfileProfessor Sang Ouk KimSoft Nanomaterials Laboratory (http://snml.kaist.ac.kr)Department of Materials Science and EngineeringKAIST

2020.10.29 View 9949 -

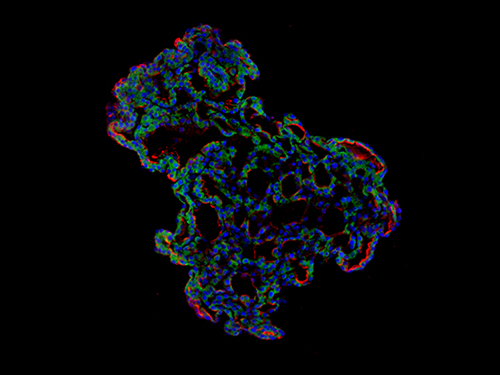

'Mini-Lungs' Reveal Early Stages of SARS-CoV-2 Infection

Researchers in Korea and the UK have successfully grown miniature models of critical lung structures called alveoli, and used them to study how the coronavirus that causes COVID-19 infects the lungs.

To date, there have been more than 40 million cases of COVID-19 and almost 1.13 million deaths worldwide. The main target tissues of SARS-CoV-2, the virus that causes COVID-19, especially in patients that develop pneumonia, appear to be alveoli – tiny air sacs in the lungs that take up the oxygen we breathe and exchange it with carbon dioxide to exhale.

To better understand how SARS-CoV-2 infects the lungs and causes disease, a team of Professor Young Seok Ju from the Graduate School of Medical Science and Engineering at KAIST in collaboration with the Wellcome-MRC Cambridge Stem Cell Institute at the University of Cambridge turned to organoids – ‘mini-organs’ grown in three dimensions to mimic the behaviour of tissue and organs.

The team used tissue donated to tissue banks at the Royal Papworth Hospital NHS Foundation Trust and Addenbrooke’s Hospital, Cambridge University NHS Foundations Trust, UK, and Seoul National University Hospital to extract a type of lung cell known as human lung alveolar type 2 cells. By reprogramming these cells back to their earlier ‘stem cell’ stage, they were able to grow self-organizing alveolar-like 3D structures that mimic the behaviour of key lung tissue.

“The research community now has a powerful new platform to study precisely how the virus infects the lungs, as well as explore possible treatments,” said Professor Ju, co-senior author of the research.

Dr. Joo-Hyeon Lee, another co-senior author at the Wellcome-MRC Cambridge Stem Cell Institute, said: “We still know surprisingly little about how SARS-CoV-2 infects the lungs and causes disease. Our approach has allowed us to grow 3D models of key lung tissue – in a sense, ‘mini-lungs’ – in the lab and study what happens when they become infected.”

The team infected the organoids with a strain of SARS-CoV-2 taken from a patient in Korea who was diagnosed with COVID-19 on January 26 after traveling to Wuhan, China. Using a combination of fluorescence imaging and single cell genetic analysis, they were able to study how the cells responded to the virus.

When the 3D models were exposed to SARS-CoV-2, the virus began to replicate rapidly, reaching full cellular infection just six hours after infection. Replication enables the virus to spread throughout the body, infecting other cells and tissue.

Around the same time, the cells began to produce interferons – proteins that act as warning signals to neighbouring cells, telling them to activate their antiviral defences. After 48 hours, the interferons triggered the innate immune response – its first line of defence – and the cells started fighting back against infection.

Sixty hours after infection, a subset of alveolar cells began to disintegrate, leading to cell death and damage to the lung tissue.

Although the researchers observed changes to the lung cells within three days of infection, clinical symptoms of COVID-19 rarely occur so quickly and can sometimes take more than ten days after exposure to appear. The team say there are several possible reasons for this. It may take several days from the virus first infiltrating the upper respiratory tract to it reaching the alveoli. It may also require a substantial proportion of alveolar cells to be infected or for further interactions with immune cells resulting in inflammation before a patient displays symptoms.

“Based on our model we can tackle many unanswered key questions, such as understanding genetic susceptibility to SARS-CoV-2, assessing relative infectivity of viral mutants, and revealing the damage processes of the virus in human alveolar cells,” said Professor Ju. “Most importantly, it provides the opportunity to develop and screen potential therapeutic agents against SARS-CoV-2 infection.”

“We hope to use our technique to grow these 3D models from cells of patients who are particularly vulnerable to infection, such as the elderly or people with diseased lungs, and find out what happens to their tissue,” added Dr. Lee.

The research was a collaboration involving scientists from KAIST, the University of Cambridge, Korea National Institute of Health, Institute for Basic Science (IBS), Seoul National University Hospital and Genome Insight in Korea.

- ProfileProfessor Young Seok JuLaboratory of Cancer Genomics https://julab.kaist.ac.kr the Graduate School of Medical Science and EngineeringKAIST

2020.10.26 View 13504

'Mini-Lungs' Reveal Early Stages of SARS-CoV-2 Infection

Researchers in Korea and the UK have successfully grown miniature models of critical lung structures called alveoli, and used them to study how the coronavirus that causes COVID-19 infects the lungs.

To date, there have been more than 40 million cases of COVID-19 and almost 1.13 million deaths worldwide. The main target tissues of SARS-CoV-2, the virus that causes COVID-19, especially in patients that develop pneumonia, appear to be alveoli – tiny air sacs in the lungs that take up the oxygen we breathe and exchange it with carbon dioxide to exhale.

To better understand how SARS-CoV-2 infects the lungs and causes disease, a team of Professor Young Seok Ju from the Graduate School of Medical Science and Engineering at KAIST in collaboration with the Wellcome-MRC Cambridge Stem Cell Institute at the University of Cambridge turned to organoids – ‘mini-organs’ grown in three dimensions to mimic the behaviour of tissue and organs.

The team used tissue donated to tissue banks at the Royal Papworth Hospital NHS Foundation Trust and Addenbrooke’s Hospital, Cambridge University NHS Foundations Trust, UK, and Seoul National University Hospital to extract a type of lung cell known as human lung alveolar type 2 cells. By reprogramming these cells back to their earlier ‘stem cell’ stage, they were able to grow self-organizing alveolar-like 3D structures that mimic the behaviour of key lung tissue.

“The research community now has a powerful new platform to study precisely how the virus infects the lungs, as well as explore possible treatments,” said Professor Ju, co-senior author of the research.

Dr. Joo-Hyeon Lee, another co-senior author at the Wellcome-MRC Cambridge Stem Cell Institute, said: “We still know surprisingly little about how SARS-CoV-2 infects the lungs and causes disease. Our approach has allowed us to grow 3D models of key lung tissue – in a sense, ‘mini-lungs’ – in the lab and study what happens when they become infected.”

The team infected the organoids with a strain of SARS-CoV-2 taken from a patient in Korea who was diagnosed with COVID-19 on January 26 after traveling to Wuhan, China. Using a combination of fluorescence imaging and single cell genetic analysis, they were able to study how the cells responded to the virus.

When the 3D models were exposed to SARS-CoV-2, the virus began to replicate rapidly, reaching full cellular infection just six hours after infection. Replication enables the virus to spread throughout the body, infecting other cells and tissue.

Around the same time, the cells began to produce interferons – proteins that act as warning signals to neighbouring cells, telling them to activate their antiviral defences. After 48 hours, the interferons triggered the innate immune response – its first line of defence – and the cells started fighting back against infection.

Sixty hours after infection, a subset of alveolar cells began to disintegrate, leading to cell death and damage to the lung tissue.

Although the researchers observed changes to the lung cells within three days of infection, clinical symptoms of COVID-19 rarely occur so quickly and can sometimes take more than ten days after exposure to appear. The team say there are several possible reasons for this. It may take several days from the virus first infiltrating the upper respiratory tract to it reaching the alveoli. It may also require a substantial proportion of alveolar cells to be infected or for further interactions with immune cells resulting in inflammation before a patient displays symptoms.

“Based on our model we can tackle many unanswered key questions, such as understanding genetic susceptibility to SARS-CoV-2, assessing relative infectivity of viral mutants, and revealing the damage processes of the virus in human alveolar cells,” said Professor Ju. “Most importantly, it provides the opportunity to develop and screen potential therapeutic agents against SARS-CoV-2 infection.”

“We hope to use our technique to grow these 3D models from cells of patients who are particularly vulnerable to infection, such as the elderly or people with diseased lungs, and find out what happens to their tissue,” added Dr. Lee.

The research was a collaboration involving scientists from KAIST, the University of Cambridge, Korea National Institute of Health, Institute for Basic Science (IBS), Seoul National University Hospital and Genome Insight in Korea.

- ProfileProfessor Young Seok JuLaboratory of Cancer Genomics https://julab.kaist.ac.kr the Graduate School of Medical Science and EngineeringKAIST